- Production Machines

- Other Manufacturing Equipment

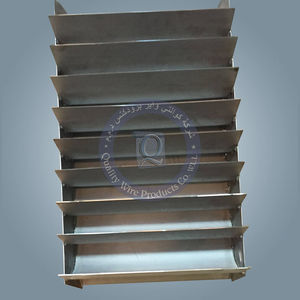

- Slot wedge wire screen

- Quality Wire Products WLL

- Products

- Catalogs

- News & Trends

- Exhibitions

V-shaped wedge wire screen slot

Add to favorites

Compare this product

Characteristics

- Construction

- slot, V-shaped

Description

Wedge wire is a welded steel structure, mainly used for filtration.

It consists of surface profiles, usually V-shaped.

The distance between the surface profiles is controlled very accurately, as it forms the slot through which the filtrate flows.

As a result of modern technology of welding, different wires may be used, various slots in one wedge wire screen, as well as different distances between supporting wires can be created.

It is used for separating solids from liquids, retaining media, filtering, sizing, dewatering, collecting, and distributing.

Advantages

Non-blocked-up.

High-precision slot sizes.

Easy to clean.

Low pressure-drop.

Strong construction.

Wedge wire screens are available in a wide variety of shapes and sizes, almost all shapes and sizes can be developed to fit customers´ requirements.

Wedge Wire Screens are V wire screens normally made in tubular form with slot opening from 50 Microns to 25MM opening which are either used in tubular form or cut and levelled and used as flat bed screens.

Manufacturing Process

Wedge wire Screens are manufactured with Triangular Wire rigidly welded to support rods mounted on a circular die and the welding is done with circular disc continuously at each point of contact resulting in forming a tubular form. These tubular form screen can either be used in tubular form or further opened and flattened according to the requirements.

We can offer screens from 12MM diameter till 650MM dia with length of the screens varies from 2.4Mtr to 6Mtr according to the customer requirement.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.