- Building - Construction

- Production of building materials

- Stationary concrete batching plant

- Quangong Machinery Co., Ltd.

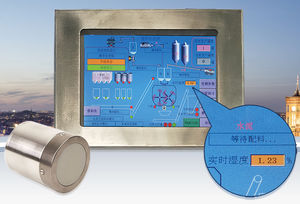

Stationary concrete batching plant automatic

Add to favorites

Compare this product

Characteristics

- Mobility

- stationary

- Other characteristics

- automatic

Description

It can be selected according to the type of local raw materials, with 3 bins to 6 bins to choose, and the amount of multiple materials can be set in the corresponding proportion. The function is to ensure the product quality and reduce the cost. The raw materials are weighed automatically by the automatic batching system and transported to the lifting hopper, which is lifted into place to pour the raw materials into the mixer for mixing.

Screen size:50*50mm

Bin volume: 4*13m³/bin (Main Material) + 2*9m³/bin (Facemix)

Measurement accuracy & range:

1) Batcher for Main Aggregates

Measuring Range: 4*400-2000kg

Weighing Accuracy: ≤ ±2%

2) Batcher for Facemix

Measuring Range: 180-1800kg

Weighing Accuracy: ≤ ±2%

Belt Conveyor:

1) Power of Batcher for Main Aggregate: 7.5Kw+2.2kw, Belt width B800

2) Power of Batcher for Facemix: 2.2kw,Belt widthB500

Cycle Time of Batching: 40 s

Remark: Customized requirements can be made according to customer's choice of batching system.

Catalogs

No catalogs are available for this product.

See all of Quangong Machinery Co., Ltd.‘s catalogsOther Quangong Machinery Co., Ltd. products

Other Machinery for Block Making

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.