- Products

- Catalogs

- News & Trends

- Exhibitions

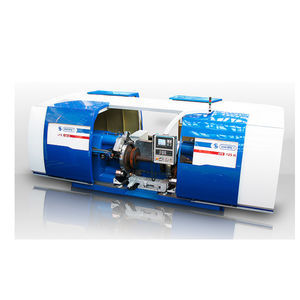

CNC lathe KKB 150 Nverticalsingle-columnfor metal

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Structure

- single-column

- Applications

- for metal, drilling, for wheels

- Associated function

- boring

- Diameter

2,000 mm

(78.74 in)- Spindle speed

400 rpm

(2,513.274 rad.min-1)- Nominal power

363 kW

(493.5 hp)- Overall lenght

6,800 mm

(268 in)- Overall height

7,200 mm

(283 in)

Description

The KKB 150 N Vertical Turning Lathe is single-column Wheel Boring Machine specifically designed for productive machining of railway wheels with two railheads.

The machine tool can perform the following turning operations controlled by technological program:

Wheel hub fine boring

-Hub facing

-Chamfering

-Wheel hub rough boring with 1-mm allowance on each side.

With a special equipment, it is possible to extend the machine capabilities to the following

operations:

-Machining of solid wheels

-Machining of wheel centres

-Boring of tyres

-Drilling of assist oil injection holes in wheel hubs.

For wheel production purposes a double railhead version of increased productivity can be provided.

MAIN FEATURES

-Machine column and cross-rail combined into a single-piece (monolithic stucture)

-Major body components made as extremely rigid, heavily ribbed box-type, high-grade grey iron castings providing maximum vibration damping capabilities during cutting process;

-Main drive powered by modular torque motor with continuously variable speed control

-Workpiece measuring probe (of Renishaw or equivalent make) mounted in tool seat

-Solid forged steel railhead ram equipped with a Coromant CAPTO® quick change tool adapter and HSK® angle machining head

-Tool / toolhead magazines.

Catalogs

No catalogs are available for this product.

See all of Rafamet‘s catalogsRelated Searches

- Turning center

- CNC turning center

- 2-axis turning center

- Milling machine

- High-performance turning center

- 3-axis turning center

- 3-axis milling machine

- Vertical turning center

- High-productivity turning center

- Heavy-duty turning center

- Milling turning center

- Vertical milling machine

- Compact turning center

- Precision turning center

- Drilling turning center

- Drilling turning machine

- Large part turning center

- Automatic milling machine

- 4-axis turning center

- Boring turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.