- Products

- Catalogs

- News & Trends

- Exhibitions

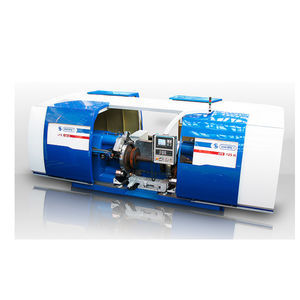

Flaw measuring system SP 125 Ndirect-contactCNCcontinuous

Add to favorites

Compare this product

Characteristics

- Measured physical value

- flaw

- Technology

- direct-contact

- Operating mode

- CNC, continuous

- Measured material

- wheel

- Applications

- for the automotive industry

Description

The measuring station SP 125 N is a CNC, automatic special-purpose measuring device, designed for precise determination of the wear of regenerated wheelsets, dismounted from the rail vehicle.

Basically, the device is adapted to work in roll-through arrangement (portal machine). The wheelsets are rolled onto the machine from the operating site to the elevator.

After lifted, the wheelset is automatically centered and clamped in the centers. It's possible to work in roll-in roll-out arrangement.

Depending on the equipment configuration, the device measures:

-Wheels profile shape - continous measurement from the top of the flange to the chamfer at the outer face;

-Wheels tread diameters, including wear;

-Back to back distance with wheels inner faces warp (dynamic measurement);

-Wheels tread radial run-out (dynamic measurement);

-Wheels rim width;

-Flanges width and height;

-Flanges inclination (dimension qR);

-Wheels equivalent conicity;

-Wheels polygonization;

-Axle diameter;

-Axle radial run-out;

-Distance between inner faces of rims and fronts of fore-hubs on the wheelset axle (dimension C - C' );

-Determination of the degree of wear and the location of the brake discs installed:

*In wheel discs

*On the axle between the wheels

(including brake discs width measurement)

MAIN FEATURES

-Roll-through / Roll-in Roll-out arrangement;

-Can be used as an independent measuring station;

-Can be used in the technological line of wheelsets regeneration;

-Creating a database of wheelsets with the possibility of optimizing the technological process of their regeneration.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Rafamet‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.