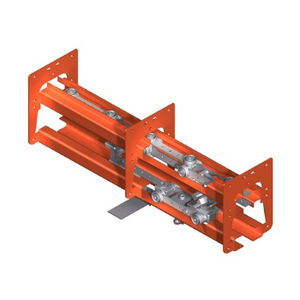

Chain conveyor F1 overheadhorizontaltransport

Add to favorites

Compare this product

Characteristics

- Technology

- chain, overhead

- Form

- horizontal

- Function

- transport

- Construction

- compact, flexible, inverted

- Transported product

- parts

- Sector

- construction, for assembly lines

- Other characteristics

- power and free

- Maximum load

300 kg

(661.387 lb)

Description

Power & Free conveyors are based on a twin-track system. The top track is used for the power chain and the bottom track for the carrier trolleys. On an equal pitch pusher dogs are fitted in the power chain and are used to pull the carriers around the system. The movable cams of the pusher dogs latch onto the trolley to form an interlink connection.

Stop stations are used to disengage the link between the power chain and trolleys. When a stop station is closed the carrier will stop while the power chain keeps moving. Because of the pusher dog and trolley design multiple carriers can buffer behind a stop station.

The F1 Inverted Power & Free system is based on the original TELEFLEX T1 Power & Free overhead conveyor system. The system can transport loads up to 300kg.

F1 Inverted Power and Free

• Compact , Simple and Flexible

• Stable Product Carrier

• Standard Components

• Vertical Rises and Falls

• Minimum bend radius 750mm

• Reliable & Low MaintenanceCompact , Simple and Flexible

Catalogs

No catalogs are available for this product.

See all of RAIL TECHNIEK‘s catalogsOther RAIL TECHNIEK products

Overhead Conveyors - Power and Free systems

Related Searches

- Rail conveyor

- Transporting conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Electric drive conveyor

- Drag chain conveyor

- Stainless steel conveyor

- Food conveyor

- Modular conveyor

- Screw conveyor

- Automatic conveyor

- Vertical rail conveyor

- Compact conveyor

- Part conveyor

- Conveyor for the automotive industry

- Construction conveyor

- Flexible conveyor

- Assembly conveyor

- Logistic conveyor

- Rail-mounted conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.