- Production Machines

- Cutting Machine

- Rotary blade cutting line

- RALC ITALIA Srl

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

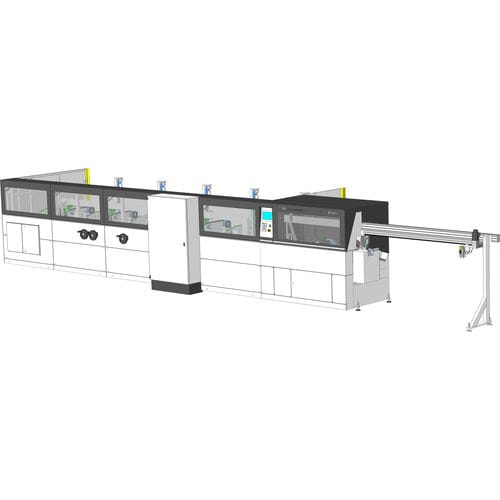

Rotary blade cutting line KRONOSfor steelfor aluminumfor brass

Add to favorites

Compare this product

Characteristics

- Technology

- rotary blade

- Material

- for steel, for aluminum, for brass

- Product handled

- tube

- Control type

- CNC

- Associated function

- chamfering, marking, deburring

- Configuration

- compact

- Other characteristics

- automatic, programmable, high-performance, precision, steel bar cutting

- Tube diameter

50 mm, 60 mm, 80 mm

(2 in, 2 in, 3 in)- Laser power

4,000 W, 5,500 W

Description

Automatic sawing machine with circular blade. Particularly suitable for cutting short pieces and designed to favour the accessory processes. Thanks to the external orientation of the blade and its structural conformation, the Kronos sawing machine allows an integrated production system, being easily coupled to various types of machining units (chamfer, marking, Measurement...).

The new Kronos model represents the latest development in integrated solutions technology.

The cutting line is fully integrated with the P15K exhaust clamp to allow the workpiece to be taken in the cut piece, bringing it to the desired fixed position, thus favouring any subsequent machining (deburring, bevelling, etc.).

The Ø10 ÷ 60 mm tubes can be cut to size and then tightened by the clamp and taken for transport in a fixed position.

The P15K clamp, handled by linear module with brushless motor, has been conceived to be directly integrated with successive machining stations.

The recordings, simple and fast, are all programmable by the operating panel of the sawing machine.

High speed cutting line specially designed in a single bearing body to ensure stability and precision.

Compact machine, with reduced dimensions.

Cutting head designed to reduce waste and feeder wagon electronically controlled.

Cutting head

High-performance cutting head with no-play gears and continuous speed variation by means of inverter.

Head handling with oleodynamic cylinder and proportional valve. Blade lubrication with water/emulsion or with microlubrication (option).

Catalogs

Kronos

2 Pages

Related Searches

- Metal sawing machine

- Automatic sawing machine

- Circular sawing machine

- Precision sawing machine

- Tube saw

- Aluminum sawing machine

- Steel sawing machine

- Vertical sawing machine

- Sawing machine with cooling system

- Hydraulic sawing machine

- CNC sawing machine

- Bar sawing machine

- High-performance sawing machine

- PLC-controlled sawing machine

- Cutting line

- Metal cutting line

- Automatic cutting line

- Copper sawing machine

- Blade cutting line

- Rotary blade cutting line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.