- Materials - Tools - Components

- Standard Mechanical Component

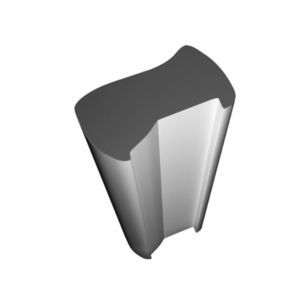

- Metal profile

- Rathbone Precision Metals, Inc.

Cold-drawn profile steel alloyTfor the automotive industry

Add to favorites

Compare this product

Characteristics

- Material

- steel alloy

- Configuration

- T

- Applications

- industrial, for the automotive industry

- Other characteristics

- cold-drawn

- Width

0.315 in

- Height

0.955 in

Description

Rathbone Precision Metals, Inc. manufactures this T-pin profile for use in an automotive steering column assembly. The cold drawn process, delivers improved mechanical properties, which enables the customer to design thinner sections with greater tensile strength than a machining application would allow. We are able to hold the specified corner radius as well as maintain uniform tip radii and accurate profile symmetry, even on the thin sections – the .315″ width of the profile is held to ±.005″ tolerances, while the .955″ height is accurate to within ±.002″.

We manufacture this profile in 1035 Alloy Steel, and supply them to the customer in 8′ bar lengths, with a 125Ra surface finish, fully tested and inspected per the their specifications.

To learn more about this project, or how a cold rolled or cold drawn profile could benefit your application, contact Rathbone today.

Capabilities Applied/Processes -

Roll & Die Design and Manufacturing

Our unique capabilities allow us to hold dimensional tolerances on thin sections while maintaining profile symmetry as well as holding tight tip edge tolerances.

Customer Benefits: -

Improved mechanical properties of cold work allows customer to design thinner sections

Provides better surface finish over machined option

Accurate profile symmetry

Uniform tip radii

Overall Profile Dimensions -

Length: 8′ Long Bars

Tolerances -

Width: ±.005″

Height: ±.002″

Material Used -

1035 Alloy Per SAE 1035

Max Material Finish -

125 Ra

Estimated Profile Weight -

.3501 lbs per ft

Standards Met -

Per Customer Supplied Specifications

VIDEO

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.