- Materials - Tools - Components

- Standard Mechanical Component

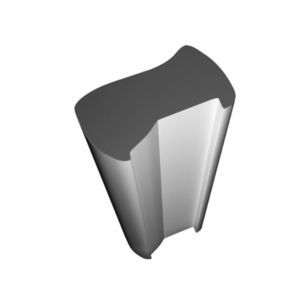

- Stainless steel profile

- Rathbone Precision Metals, Inc.

Stainless steel profile industrial

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Applications

- industrial

- Width

0.75 in

- Height

0.65 in

Description

This retaining ring segment for a high pressure water pipe application highlights Rathbone Precision Metals, Inc.’s ability to manufacture parts that are tougher, more uniform, and less expensive than a machined version. One of the tolerance requirements for this project stipulated that the sharpness of the tooth tips were not to exceed .005″ radius. This precise sharpness could only be achieved by using our cold drawn process or by expensive secondary machining. Our expert design team created a combination of cold rolling and cold drawing processes to achieve .004” geometrical line tolerances on the finished product.

The .760″ wide by .445″ high profiles, drawn from Stainless Steel to a 125 Ra finish, are heat treated per customer specifications. An adiabatic process is used to precisely cut the profile into various lengths, with ± .005″ accuracy and absolutely no kerf – no further machining is needed.

Our team is ready to work with you to design tooling and produce your profiles in an effort to cost-effectively produce parts, no matter how complex, using a cold forming technique.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Capabilities Applied/Processes -

Die Design and Manufacturing

Our unique capabilities allow us to hold tooth sharpness to .005″.

High volume adiabatic shearing and saw cutting

Overall Profile Dimensions -

Lengths: 3’ to 6’ In a Heat Treated Condition

Up to 12′ Mill Lengths Available if Supplied in As Cold Rolled Condition

Tolerances -

Profile line as tight as Width: .004″

Height: .004″

Max Material Finish -

125 Ra

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.