- Power Transmission - Mechanical components

- Mechanical Transmission

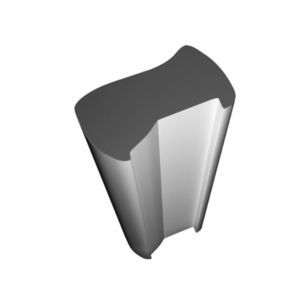

- Cylindrical gear

- Rathbone Precision Metals, Inc.

Cylindrical gear helical-toothedcarbon steelindustrial

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Teeth

- helical-toothed

- Material

- carbon steel

- Applications

- industrial

- Other characteristics

- precision

Description

Manufactured at Rathbone Precision Metals, Inc. for use in a mechanical fuel injector application, this asymmetrical gear profile is only one part of an entire gear configuration, which is produced to precise dimensions that are critical to the functionality of the final assembly. Our cold working techniques and precision die designs provided a better surface finish and eliminated the need for hobbing, saving the customer valuable time and money.

Fabricated from 1215 Carbon Steel, we used a cold draw process to create this .900″ wide by .770″ high gear profile with 63 Ra surface finish and precisely formed teeth that required no additional machining. Dimensional tolerances were held to ±.002″, straightness was within .020″ per foot.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Product Application -

This gear profile is used in a mechanical fuel injector application.

Capabilities Applied/Processes -

Die Design and Manufacturing

Our Unique Capabilities Allow us to provide this non-standard gear profile that has a gear configuration that is only one part of the entire profile.

Customer Benefits: -

Cold drawn gear teeth eliminates hobbing

Provides better surface finish than hobbing

Overall Profile Dimensions -

Width: .900″

Height: .7700″

Bar Lengths: 12″

Tolerances -

±.002″

Straightness: .020″ Per Foot

Material Used -

1215 Carbon Steel

Max Material Finish -

63 Ra as Cold Drawn

Estimated Profile Weight -

1.9 lbs

Standards Met -

Per Customer Supplied Specifications

VIDEO

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.