- Materials - Tools - Components

- Standard Mechanical Component

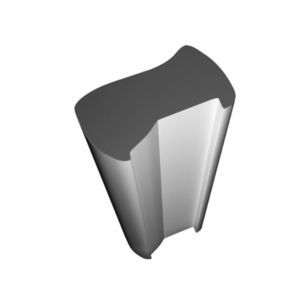

- Alloy profile

- Rathbone Precision Metals, Inc.

Alloy profile stainless steelrodindustrial

Add to favorites

Compare this product

Characteristics

- Material

- alloy, stainless steel

- Configuration

- rod

- Applications

- industrial

Description

Our expertise with cold working a variety of alloys led to Rathbone Precision Metals, Inc. being awarded a contract to produce this Orthopedic Rod for use in a demanding medical application. We devised a single tool set that permitted us to cold draw either 455 or 304 Stainless to the customer’s tensile and yield strength requirements necessary for this medical application.

These .300″ diameter rods, with .20″ root diameters, were drawn to a smooth 63 Ra surface finish and cut to precise 6.599″ to 6.638″ lengths, all within ±.0015″ tolerances. Our ability to precisely adjust the material properties during the cold draw process was critical to the success of this project.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Capabilities Applied/Processes - -

Die Design and Manufacturing

Our unique capabilities allow us to draw “PH” grades of material into

varies profile configurations.

Customer Benefits: -

Multiple grades using of materials using 1 set of tools

Tight tolerance profiles in difficult to work alloy grades

Tailored mechanical properties

Overall Profile Dimensions -

O.D.: Ø.300″

Length: 6.599″ to 6.638″

Tolerances -

±.0015″

Material Used -

455 & 304 Stainless Steel Grade Material

Max Material Finish -

63 Ra

Estimated Profile Weight -

.204 lbs per ft

Standards Met -

Per Customer Supplied Specifications

Product Description -

Orthopedic Rod

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.