- Power Transmission - Mechanical components

- Mechanical Transmission

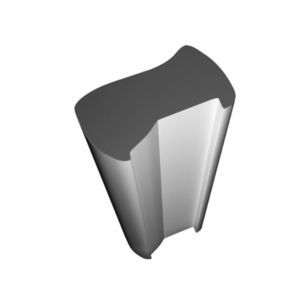

- Cylindrical gear

- Rathbone Precision Metals, Inc.

Cylindrical gear helical-toothedsteel

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Teeth

- helical-toothed

- Material

- steel

Description

When it comes to close-tolerance manufacturing of complex shapes from leaded alloy steel, Rathbone Precision Metals, Inc.’s cold drawn expertise enables us to produce profiles that are superior in quality and less costly than their machined counterparts.

Using 86L20 Steel, we use a cold draw process to form the unique tooth configuration per customer specifications, which eliminates the need for broaching. In addition, we control the corners, and fillet radii to ±.005″ tolerance, that would be difficult to cost effectively achieve by broaching. With a major diameter of 1.219″, minor diameter of .906″, and 125 Ra max finish, the profile is delivered to the customer in average 14′ random mill bar lengths.

This complex shape is cold drawn with much less waste and with greater precision than the machined alternative offered, saving the customer time and money.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Product Application -

This gear profile is used in truck clutch applications.

Capabilities Applied/Processes -

Die Design and Manufacturing Our unique capabilities allow us to provide an uncommon tooth profile configuration with controlled corner and fillet radii.

Customer Benefits: -

Unique Tooth Profile Configuration Saves on Broaching Costs Controlled Corner/Fillet Radii

Overall Profile Dimensions -

Overall Diameter:

Major: Ø1.219

Minor: Ø.906

Lengths:14′ Random Mill Bar Lengths

Tolerances -

±.002″

Material Used -

86L20 Steel

Max Material Finish -

125 Ra

Estimated Profile Weight -

2.7948 lbs per ft

Industry for Use -

Automotive

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.