- Materials - Tools - Components

- Standard Mechanical Component

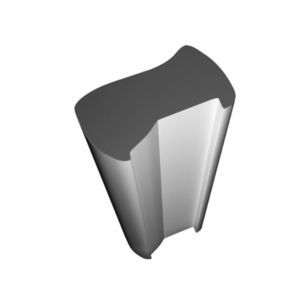

- Metal profile

- Rathbone Precision Metals, Inc.

Metal profile U-shapedindustrialcold-drawn

Add to favorites

Compare this product

Characteristics

- Material

- metal

- Configuration

- U-shaped

- Applications

- industrial

- Other characteristics

- cold-drawn

- Width

0.512 in

- Height

0.15 in

Description

This cold drawn profile is produced by Rathbone Precision Metals, Inc. for the linear motion industry. This carriage insert profiles are produced in bearing quality 52100 steel and requires exacting tolerances and surface finish to provide low-weight solutions for critical high performance applications.

Rathbone produces this carriage insert to a profile of line tolerance of 0.002” with a critical web dimension that is held to within .001” over the length of the 8 foot bars provided by Rathbone to the customer. Straightness of the 8 foot bars we supply is held to 0.015” per foot maximum.

Being that this for a wear application, surface hardness and surface finish of the carriage insert are both critical. Rathbone produces this profile with a surface decarburization limit of partial and full being held to with 0.002”. This supports the customer achieving the required surface hardness when heat treating the insert. The surface finish as supplied Rathbone is 63 µRa maximum.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Product Application -

This Carriage Insert is used in linear motion application.

Capabilities Applied/Processes -

Die Design and Manufacturing to hold tighter than industry dimensional tolerances, surface finishes, while assuring a limited layer of surface decarburization.

Customer Benefits: -

Rathbone cold drawn profile provides an excellent solution for a contoured part that would be challenging to machine.

Tight tolerances better than industry standard.

Improved as cold drawn surface finish.

Tolerances -

Profile of line of 0.002”

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.