- Materials - Tools - Components

- Standard Mechanical Component

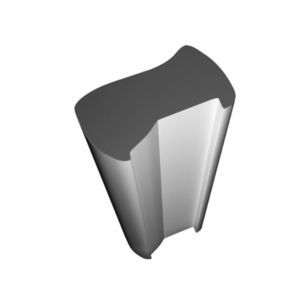

- Stainless steel profile

- Rathbone Precision Metals, Inc.

Stainless steel profile U-shapedindustrialcold-rolled

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Configuration

- U-shaped

- Applications

- industrial

- Other characteristics

- cold-rolled

- Width

0.75 in

- Height

0.65 in

Description

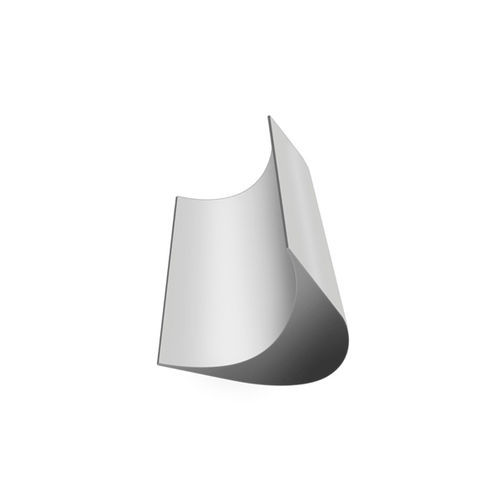

Rathbone Precision Metals, Inc. produces this turbine bucket blade stock for customers in the power generation industry. Due to its asymmetrical shape, the profile was difficult and costly to machine in large volume. After reviewing the customer specifications, Rathbone proposed a cold roll process to produce the profiles. Our expert in-house design team developed tooling that would form the unbalanced profile, improve the tolerances, provide a better surface finish, and do it more economically, with less waste than machining.

We fabricate this blade stock from 403/410 Stainless Steel, rolled to a .750″ width and .650″ height and with a 32 Ra or better surface finish. Tolerances are held to ±.010″, the deviation across the web is less than ±.002″, and the straightness is accurate to within ±.030″ per foot. We supply the customer with both 3′ and 6′, heat treated bar lengths as well as 12′ lengths in cold rolled condition.

Rathbone was proud of its ability to provide this customer with a superior quality product at a significant cost savings. We store and maintain the tooling on this project, as we do with all others, to produce this stock on an ongoing basis.

To learn more about this profile as well as others, or how cold drawn and cold rolled profiles could benefit your application, please contact Rathbone today.

Product Application -

This asymmetrical turbine bucket blade stock is used in a steam turbine application.

Capabilities Applied/Processes -

Roll Design and Manufacturing

Our unique capabilities allow us to cold roll an unbalanced profile

Catalogs

No catalogs are available for this product.

See all of Rathbone Precision Metals, Inc.‘s catalogsOther Rathbone Precision Metals, Inc. products

What We've Made

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.