- Hydraulics - Pneumatics

- Filter and Separator

- Liquid filter

- REBER SYSTEMATIC GMBH + CO. KG

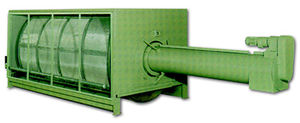

Liquid filter KBF/Ebeltpapercontinuous

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid

- Filtration element

- belt

- Material

- paper

- Cleaning

- continuous

- Other characteristics

- compact

Description

The logical further development of the KBF filter. In this case the filtering is performed not with paper but with a continuous fabric belt made of plastic. Basically the CBF filter works by the KBF principle, i.e. with no relative rotation between the filter belt, the filter wheels and the sludge drivers. In special cases filter paper can be used in addition either temporarily or permanently. This does not require any conversions to the machine.

Principle

A strong, continuous metal link belt is tensioned in a half shell form, around two co-rotating pulley wheels. The angle of contact at the pulleys is approx. 180°. The link belt is driven by a geared motor acting via a drive shaft. The continuous filter band is inserted between the metal link belt - the carrier belt - and the filter wheels. This fabric filter belt is tensioned separately and moved by friction. The Filtration trough is sealed on all sides. The medium to be filtered is directed into the trough via the centrally positioned inlet pipe. The cleaned medium is transferred vertically down into the clean tank via separate outlets. An intentional turbulent zone at the infeed - arc screen effect - keeps the filter belt free of dirt deposits and hence permeable in this zone. The particles settle in the calm zone of the filtration trough where they form a filter cake. This filter cake serves as an additional filter layer. A pool forms slowly but surely as the particle deposits rise an the filter belt.

Catalogs

No catalogs are available for this product.

See all of REBER SYSTEMATIC GMBH + CO. KG‘s catalogsOther REBER SYSTEMATIC GMBH + CO. KG products

Products

Related Searches

- Liquid separator filter

- Solid classifier

- Liquids separator

- Filtration system

- Y-strainer filter

- Process classifier

- Liquid filtration system

- Compact separator filter

- Particle classifier

- Absorption filtration unit

- Self-cleaning separator

- Continuous pre-filter

- Vacuum filtration system

- Automatic filtration system

- Compact filtration system

- Horizontal filter

- Belt filter

- Drum filter

- Paper filter

- Sludge separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.