- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic pasteurizer HTST seriesfor dairy productssemi-automatic

Add to favorites

Compare this product

Characteristics

- Applications

- for dairy products

- Operating mode

- automatic, semi-automatic

Description

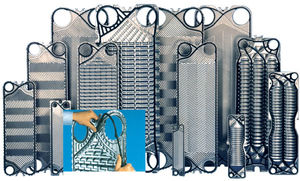

For more than 30 years REDA S.p.A. has been acting in the milk pasteurization process, using and constantly developing the plants of the series HTST (High Temperature Short Time). These plants are totally automated or semi-automatic, designed for the production of pasteurized fresh milk and by-products. Main objective of the milk pasteurization is the destruction of the contained pathogenic microorganisms: this scope is normally reached by submitting the product to a thermal treatment to high temperatures for a short period of time, followed by his quick cooling. The obtained pasteurized product will be then commercialized using the cold chain system. During the process of pasteurization REDA S.p.A. offers the following options, as well:

clarification, skimming, standardization, bactofugation;

automatic standardization milk-cream;

deaeration;

homogenization.

The pasteurizers produced by REDA S.p.A. are pre-assembled and pre-tested on a stainless steel platform, and are conceived and realized for an easy installation on site thanks to the constructive philosophy “Plug-and-Play”

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.