Laser welding machine i-PRO 2500MIGsubmerged arcMAG

Add to favorites

Compare this product

Characteristics

- Technique

- laser, MIG, submerged arc, MAG

- Operational mode

- automatic

- Applications

- for beams

- Other characteristics

- integrated, vertical

Description

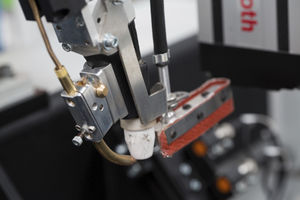

Welding beams in vertical position and by making them pass through the welding arc makes economic sense when production quantities are large and part sizes suit this process. The CMF I-PRO welder integrates all the equipment required for this welding technique, from the input to the output conveyors.

MIG welding processes and more often submerged arc, monofil, bifilar and tandem can be naturally integrated on different CMF I-PROs.

A device for automatically straightening flanges on leaving the welder ensures the geometry of the finished product.

According to different machine sizes, the I-PRO range enables:

• Web height from 160 to 5000 mm

• Flange width from 80 to 2500 mm

• Web thickness from 4 to 50 mm

• Flange thickness from 5 to 120 mm

• Sloped side to 8°

• Welding processes that can be integrated: MIG/MAG (mono and twin), submerged arc monofil (bifilar and tandem also available), hybrid laser

• Systems for unloading and/or turning the beam

• System for automatic beam return at line entry after the first welding

• Putting two I-PROs in line for maximum productivity

• Hybrid laser welding

• Welded beams for building construction

• Small and medium-size structures

Catalogs

No catalogs are available for this product.

See all of REEL CMF‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Laser welding system

- Metal welding system

- Precision welding system

- Arc welding system

- Standalone welding system

- Mounting machine

- Steel welding system

- Automatic mounting machine

- Semi-automatic welding system

- Integrated welding system

- MIG welding system

- High-precision welding system

- TIG welding system

- Automatic welding head

- High-speed welding system

- MAG welding system

- Assembly machine for industrial applications

- Custom welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.