Laser welding machine MIGTIGsubmerged arc

Add to favorites

Compare this product

Characteristics

- Technique

- laser, MIG, TIG, submerged arc, MAG, plasma

- Operational mode

- automatic

- Other characteristics

- longitudinal, circular

Description

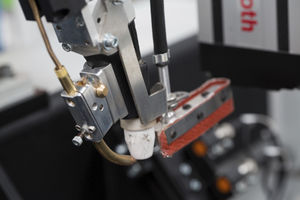

The circular welding machine is a logical complement of CMF longitudinal welders. The circular welders are for welding the end parts on shells (domed ends, connection parts, etc.), always with a goal of simplicity, reliability and productivity suited to the product.

• Automatic welding cycle

• Shell diameter from 100 mm

• Shell length up to 6 metres

• Sheet thickness between 3/10 and 12 mm according to versions

• Productivity between 20 and 200 parts an hour according to models

• Possible shell forms: cylindrical, rectangular, oval, triangular, and any other complex form (to be validated according to the radii to be made)

• Welding processes: MIG/MAG (mono and twin), TIG, Plasma, submerged arc, laser and hybrid laser

• In addition to our standard range, we examine every request to adapt our machines to the specifications of our customers

• Devices for automatically loading and unloading the shells

• Devices for automatically loading and unloading the end parts

• Integration into a production line

• Automobile: exhaust silencer and catalyser bodies, filtration components, etc.

• Motorcycle: Complex form exhaust silencer bodies

• Utility vehicles, trucks and coaches: fuel tanks, exhaust silencer and catalyser bodies, filtration components, compressed air reservoirs, etc.

• Water heaters

• Extinguisher bodies

• Pump and compressor bodies

• Compressed air reservoirs

• Various tubes for all industries

• All other applications on request…

Catalogs

No catalogs are available for this product.

See all of REEL CMF‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Laser welding system

- Metal welding system

- Arc welding system

- Precision welding system

- Standalone welding system

- Mounting machine

- Steel welding system

- Automatic mounting machine

- Semi-automatic welding system

- Integrated welding system

- MIG welding system

- High-precision welding system

- TIG welding system

- Automatic welding head

- High-speed welding system

- MAG welding system

- Assembly machine for industrial applications

- Custom welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.