Automatic rolling welding line CR TYPE

Add to favorites

Compare this product

Characteristics

- Type

- automatic

Description

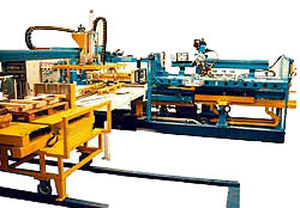

CR TYPE ROLL BENDING AND WELDING AUTOMATIC PRODUCTION LINE

It includes a high rate rolling machine and a Seamexpress welder as well as an automatic sheet picker at the input in order to achieve a fully automatic and autonomous installation. It is well suited to the production of compressed air reservoirs up to large sizes, and any other type of medium run production. Large size parts with square or rectangular cross-section are also very easy to produce with this type of line.

• Shell diameter from 1000 mm

• Shell length up to 3 metres

• Sheet thickness between 3/10 and 6 mm according to versions

• Productivity between 80 and 300 parts an hour according to models

• Changeover within 10 minutes

• Discontinuous welding, fixed shell and moving torch

• Possible shell forms: cylindrical, rectangular, oval, triangular, and any other complex form (to be validated according to the radii to be made)

• In addition to our standard range, we examine every request to adapt our machines to the specifications of our customers

• Welding processes: MIG, TIG, Plasma, submerged arc, laser

Catalogs

No catalogs are available for this product.

See all of REEL CMF‘s catalogsRelated Searches

- Bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Plate roll machine

- Metal forming machine

- Automatic forming machine

- Straightener

- Sheet metal bending cell

- Metal part straightener

- Numerical control plate bending machine

- Motorized bending machine

- Pipe-end forming machine

- Rolling bending machine

- Electric plate bending machine

- Mechanical bending machine

- Manual plate bending machine

- Tube forming machine

- Sheet metal forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.