- Packing - Handling - Logistics

- Packing and Packaging

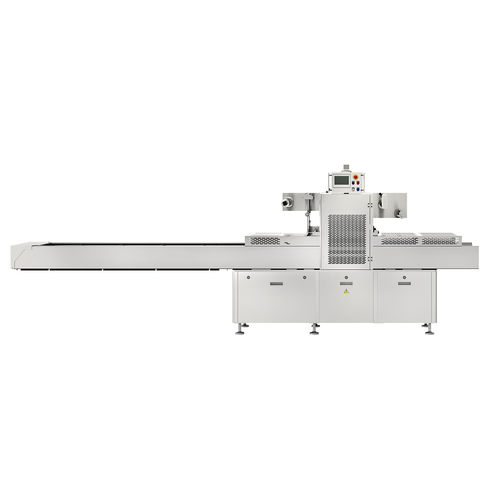

- Linear tray sealer

- Reepack S.r.l. Soc. Unip.

- Products

- Catalogs

- News & Trends

- Exhibitions

Linear tray sealer REEMATIC 150automaticfor the food industryvacuum

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Operational mode

- automatic

- Other characteristics

- for the food industry, vacuum, with modified atmosphere packaging, for the pharmaceutical industry, medical

Description

Automatic tray sealer SINGLE DIE-SET

suitable for both artisanal and industrial productions.

Ideal for packaging fresh or frozen food, and ready-meals in ambient sealing, modified atmosphere (MAP), or vacuum skin (VSP). This machine can process any type of material and it is also suitable for medical products and industrial goods applications.

Single or Multi-lane infeed conveyor. Tray transport by pushing rods guided on both sides by motor-driven chains. Step by step movement with controlled speed to adapt to any type of tray, specific product, or production environment.

Electrical motion of bottom vacuum chamber combined with pneumatic sealing and cutting in the upper part for the most efficient and reliable packaging output with the lowest maintenance cost on the market.

Robust stainless steel frame and structure for high machine durability and ideal hygienic conditions. Overall rating IP 65.

ReeMatic 150 consumes very little compressed air saving you money in both power consumption and general maintenance; and thus, increasing return on investment.

Machine height: 1815 mm

Machine width: 1040 mm

Machine length: 3195 ÷ 6820 mm

infeed conveyor length: 1000 ÷ 4000 mm

Length free loading area: 1285 ÷ 3940 mm

No. of trays to load: 2 ÷ 8

Height free loading area: 915 - 960 mm

Max diameter web roll: 280 mm

Diameter of web roll mandrel: 76 mm(3'')

Machine main movements: Electromechanical

Microprocessor Control: PLC-Siemens

Control panel: Touch-screen

Vacuum pump: 100 - 200 - 300 m3/ h

Electrical supply: 3 / N / PE 400V AC 50 Hz

Electrical power: Min. 4 Kw Max 11 Kw

Compressed Air: 7 Nl / c.

Overall Construction: Stainless-Steel / Edelstahl

Other Reepack S.r.l. Soc. Unip. products

Small/Medium output

Related Searches

- Packing machine

- Automatic packing machine

- Bagging machine

- Automatic bagging machine

- Packing machine for the food industry

- FFS bagging machine

- Bagging machine for the food industry

- Vacuum packing machine

- Shrink wrapper

- Automatic sleeve wrapping machine

- Bell type packing machine

- Horizontal bagging machine

- Sealer

- Bag packing machine

- Thermoformer

- Packing machine with sealing bar

- Automated thermoforming machine

- Shrink wrapper with shrink tunnel

- Tray sealing machine

- Packaging thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.