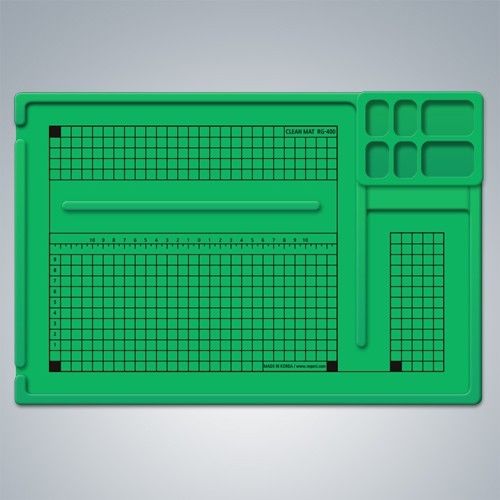

Clean mat RG-400silicone

Add to favorites

Compare this product

Characteristics

- Function

- clean

- Material

- silicone

Description

Anti-ESD Silicon Clean Mat

Electricification-preventive silicon used/Prevention of Electrostatic

Discharge/Worker`s fatigue minimized and efficiency is improved

Surface treatment for Anti-ESD

RG-400 used specially static-current preventive material for both silicon main body and and black printing

ink lines on frontal surface To reduce conductive electricty, static-current to improve repair efficiency of electronic device.

Arrangement of tiny parts in disassembly

There is storage compartment (top right) to place tiny parts against missing, neodium magnets which user additionally

purchase can be inserted at backsides of storage compartment to magnetize small parts to easily stick to tool against missing

Prevention of Electrostatic Discharge

Static-current occurred at human body or workpiece which is harmful to semiconductor parts is flown out by ground

cable (included) (Measure the value of surface resistance for our genuine mat : 10e8±2)

The function of each portion

①Ground cable - flowing occurring static-current to ground by connecting between mat and ground

(top left or bottom left)

②Storage compartment - Tiny parts are placed, also at the backside, there are grooves to insert neodium magnets to magnetize

tiny metal parts ( additional purchase)

③ANTI-STATIC LINE - Reducing occurrence of static current on mat by printed anti-ESD ink, Silicon material is withstanding

high temperature 250 celsius degrees and some chemicals

Comparasis data of half life

By comparing half life of normal silicon rubber and electrification-preventive silicon After applying electric power onto mat product,

Catalogs

No catalogs are available for this product.

See all of REGEN-I Company‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.