- Production Machines

- Plastics Processing

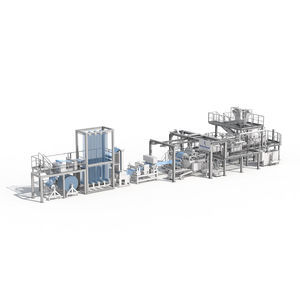

- Flat-film extrusion line

- Reifenhäuser Extrusion Technology GmbH & Co. KG

Flat-film extrusion line MIDEX plastics recyclingfor polypropylenfor CPP

Add to favorites

Compare this product

Characteristics

- Type

- flat-film, plastics recycling

- Treated material

- for polypropylen, for CPP

- Other characteristics

- 5-layers

- Applications

- for food film

Description

Cast polypropylene films (CPP film) are the standard used for packaging film in the food and industrial sectors.

Reifenhäuser MIDEX CPP

CPP films offer the best solution regarding transparency (appearance), printability, metallization, and sealability.

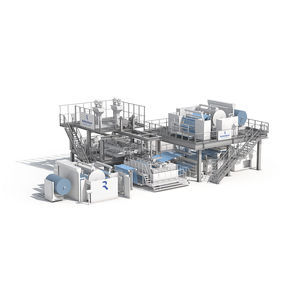

Midex CPP lines cover the entire bandwidth of these applications. The line concept is tailor-made for a custom film product and to meet specific customer requirements.

A melt is produced by an extruder from a PP granulate. Up to 5 individual layers are superimposed by a feedblock and expanded in a flat die to widths up to 7 m. The downstream casting process includes a cooled roll to finish the film to the required properties.

Optimized line concept

Midex CPP lines not only feature a modular design that permits a customized line concept based on field-proven and custom components.The lines also feature high overall equipment

ffectiveness (OEE) and sustainability.

Raw material and product sustainability

High-cost raw materials are used for function layers and external coatings. The key factor here is to apply the feedstock sparingly and efficiently. Reifenhauser technology in the feedblockand fiat die produce extremely thin but effective coatings. This saves valuable raw materials and allows the finished film product to be recycled by using only one raw material.

Industry / Technology

-Protective film

Sustainability

-Packaging Films (CPP with BOPP)

-Recyclable products

Catalogs

No catalogs are available for this product.

See all of Reifenhäuser Extrusion Technology GmbH & Co. KG‘s catalogsOther Reifenhäuser Extrusion Technology GmbH & Co. KG products

Flat film lines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Screw extruder

- Twin-screw screw extruder

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- Cast-film extrusion line

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Blown film extrusion line

- PS screw extruder

- Extrusion line with water cooling

- PET screw extruder

- PET extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.