- Production Machines

- Plastics Processing

- Tape extrusion line

- Reifenhäuser Extrusion Technology GmbH & Co. KG

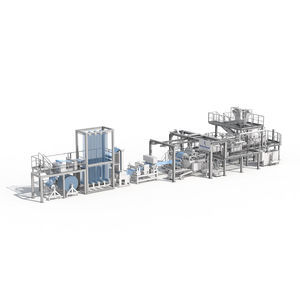

Coating extrusion line Lamicortapefor thermoplasticsfor medical applications

Add to favorites

Compare this product

Characteristics

- Type

- tape

- Treated material

- for thermoplastics

- Other characteristics

- for medical applications

- Applications

- for automotive applications

Description

From coffee packaging to truck tarpaulins, car headliners, construction film to medical and hygienic applications. Lamicor creates film composites as the optimal combination of a substrate material with a plastic coating.

The basic plant concept

The extruder in a Lamicor line produces a thermoplastic mixture from raw material, which is formed into a melt web by a slot die. This is permanently bonded to the substrate between the laminator roller and the pressure roller by pressure and heat.

Optimal Line Concept

Lamicor systems impress with their sustainability. This is achieved through the use of solvent-free technology, the usability of recyclate as well as the efficient use of raw materials and energy-saving opération. At Lamicor, it is notonly production that is characterized by sustainability: even the film produced is recyclable.

Individual components - How to use the fullpotential

The line concept of a Lamicor line is very much dépendent on the product produced. Furthermore, they can be adapted to important production parameters. Talkto usaboutyour individual needs.

Catalogs

No catalogs are available for this product.

See all of Reifenhäuser Extrusion Technology GmbH & Co. KG‘s catalogsOther Reifenhäuser Extrusion Technology GmbH & Co. KG products

Flat film lines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Screw extruder

- Twin-screw screw extruder

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- Cast-film extrusion line

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Blown film extrusion line

- PS screw extruder

- Extrusion line with water cooling

- PET screw extruder

- PET extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.