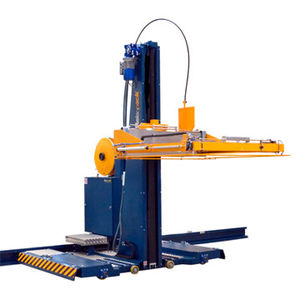

Fully-automatic strapping machine 2915palletfor palletfor industrial applications

Add to favorites

Compare this product

Characteristics

- Type

- fully-automatic

- Product applications

- pallet, for pallet, for industrial applications, for brick, for the food and beverage industry, for the food industry, for vegetables, food, for fruit, for food

- Type of strap

- for plastic straps

- Sector

- for the packaging industry, for logistics, for the food industry, for the wood industry, bottling industry, medical, for the automotive industry, for the metallurgical industry, construction

- Rate

Max.: 50 p/min

Min.: 1 p/min

- Strap width

Max.: 12 mm

(0.472 in)Min.: 10 mm

(0.394 in)

Description

The 2915 multi-station strapping machine with corner protectors is the ideal solution for producers who need to optimise the strapping of pallets with boxes. This high-speed system not only places the corner protectors automatically, but also organises the strapping area efficiently, allowing for a more logical and safe workflow at the end of the line.

With its ability to move laterally between multiple strapping stations, the 2915 allows multiple pallets to be processed simultaneously, achieving an output of over 60 pallets per hour. This is especially useful for companies that need to manage high volumes of palletised boxes, ensuring that the strapping process is carried out continuously and without interruptions.

The machine detects the corners of the pallet, precisely placing the corner protectors to protect the boxes and ensure that the load is firmly compacted before strapping. Plus, with the ability to strap at up to 20 different heights, the 2915 can accommodate a variety of pallet sizes and load configurations.

The touchscreen control panel makes it easy to program and customize up to 50 strapping programs, offering flexibility to accommodate different box types and specific packaging needs. Plus, its long-life, low-maintenance design makes the 2915 a reliable, cost-effective investment for the long term.

Thanks to its multi-station system, the 2915 strapper also keeps pallets neat and ready for strapping, maximizing time savings on pallet feeding and allowing for last-minute handling if necessary. It's a one-stop solution that ensures fast, neat and safe strapping.

Catalogs

No catalogs are available for this product.

See all of Reisopack‘s catalogsRelated Searches

- Automatic labelling machine

- Strapping machine

- Automatic strapping machine

- Labeling machine for the food industry

- Polypropylene strap strapping machine

- Vertical strapping machine

- Semi-automatic labelling machine

- Semi-automatic strapping machine

- Strapping machine for the packaging industry

- Fully-automatic strapping machine

- Pallet strapping machine

- Mobile strapping machine

- Cardboard box strapping machine

- Horizontal strapping machine

- High-speed strapping machine

- 380V three-phase strapping machine

- Lateral strapping machine

- Motorized labeling machine

- String tying machine

- Stainless steel strapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.