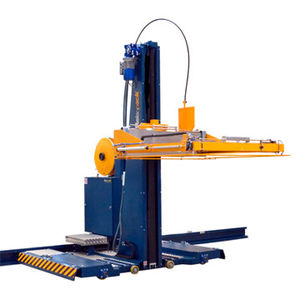

Fully-automatic strapping machine 2913palletfor palletpallet

Add to favorites

Compare this product

Characteristics

- Type

- fully-automatic

- Product applications

- pallet, for pallet, pallet, for vegetables, for fruit

- Type of strap

- for plastic straps

- Sector

- for the packaging industry, for logistics, for the food industry

- Rate

Max.: 60 p/min

Min.: 1 p/min

- Strap width

Max.: 12 mm

(0.472 in)Min.: 10 mm

(0.394 in)

Description

The 2913 pallet strapping machine with multiple strapping stations is the ideal tool to optimize the packaging process of pallets with boxes in high production volumes. This advanced system allows efficient strapping at different stations, facilitating a much faster and more orderly end-of-line organization, maximizing productivity.

The 2913 is designed to handle several loads simultaneously, reducing downtime and increasing production capacity without compromising packaging quality. This machine ensures that the boxes on the pallets are perfectly secured and protected during transport and storage, minimizing the risk of damage.

One of the main advantages is the possibility of configuring the strapping at multiple heights and the option of memorizing specific programs for different types of loads. This guarantees total flexibility, easily adapting to the various box and pallet configurations used by each producer. The strapping process is carried out quickly and accurately, compacting the load before applying the strap, ensuring everything stays firmly in place.

In addition, the machine is easy to program using its intuitive touch screen, allowing operators to customize programs to the needs of each batch. With its ability to handle high production volumes, the 2913 is ideal for companies looking for a robust, long-lasting, low-maintenance solution, ensuring efficient operations at all times.

Catalogs

No catalogs are available for this product.

See all of Reisopack‘s catalogsRelated Searches

- Strapping machine

- Automatic strapping machine

- Polypropylene strap strapping machine

- Vertical strapping machine

- Semi-automatic strapping machine

- Strapping machine for the packaging industry

- Pallet strapping machine

- Fully-automatic strapping machine

- Mobile strapping machine

- Cardboard box strapping machine

- Horizontal strapping machine

- High-speed strapping machine

- 380V three-phase strapping machine

- Lateral strapping machine

- Stainless steel strapping machine

- Box strapping machine

- Pallet strapping machine

- Strapping machine with press

- In-line strapping machine

- Production line strapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.