- Production Machines

- Other Manufacturing Equipment

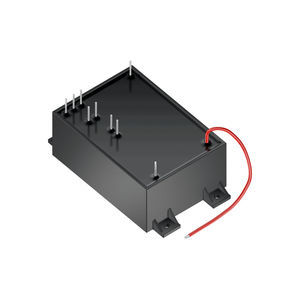

- Medical ozone generator

- relyon plasma GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Medical ozone generator MediPlas Reactoragriculturefor the food industry

Add to favorites

Compare this product

Characteristics

- Domain

- for the food industry, medical, agriculture

- Power consumption

40 W

- Ozone production

5 g/h

Description

The MediPlas Reactor is a high-performance ozone generator. Depending on the selected process parameters and the type of gas supplied, the following reactive species are formed in the reactor: Ozone, hydrogen peroxide as well as nitrogen oxides. The exact composition of the medium can be varied according to customer-specific requirements.

It is based on cold atmospheric plasma (KAP) and can be integrated into applications as a component for cleaning, sterilization and disinfection. It was developed for the food, beverage, and pharmaceutical industries. But the principle can also be used in medical technology. To learn more about MediPlas in medical applications click here.

We are looking for partners who would like to benefit from the advantages of our DBD components and integrate our modules into their systems.

Applications of the ozone generator

Pharmaceutical industry

Packaging industry

Food and beverage industry

Agriculture industry

Automotive industry

Medical technology

Dental sector

Use in Cleaning in Place

The cold atmospheric plasma components can be used wherever hygiene is an important consideration. This can be optimized by incorporating ozone into Cleaning in Place (CIP). Instead of the typical six steps, only four steps are required due to the incorporation of ozone.

Cleaning in place is a method for cleaning continuous processes without dismantling the system. The method was originally developed for the food, beverage and pharmaceutical industries. But the principle can also be used in medical technology.

VIDEO

Catalogs

No catalogs are available for this product.

See all of relyon plasma GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.