- Products

- Power driver

- relyon plasma GmbH

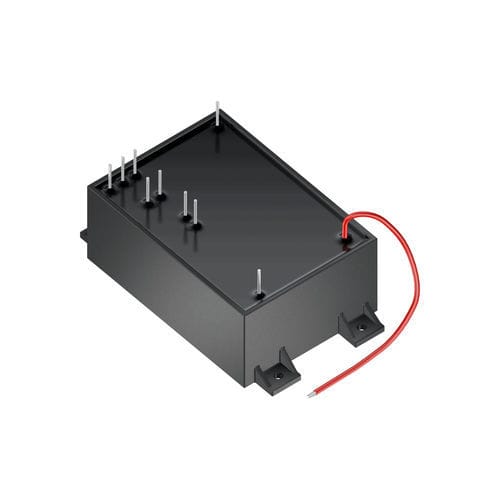

Ozone generator power driver MediPlas Driver

Add to favorites

Compare this product

Characteristics

- Options

- for ozone generator

Description

The MediPlas Driver is a driver for ozone generators. The high voltage source provides the necessary voltage power for ozone generation. The MediPlas Driver and the MediPlas Reactor from TDK can be integrated into applications as components for cleaning, sterilizing and disinfecting.

The high voltage source is designed to operate with a suitable plasma generator. The ozone generator driver converts a DC low voltage to AC high voltage using an autoresonant circuit topology. The output frequency independently adjusts to the load being operated.

Applications of the ozone generator

Pharmaceutical industry

Packaging industry

Food and beverage industry

Agriculture industry

Automotive industry

Medical technology

Dental sector

The cold atmospheric plasma components can be used wherever hygiene is an important consideration. This can be optimized by incorporating ozone into Cleaning in Place (CIP). Instead of the typical six steps, only four steps are required due to the incorporation of ozone.

Cleaning in place is a method for cleaning continuous processes without dismantling the system. The method was originally developed for the food, beverage and pharmaceutical industries. But the principle can also be used in medical technology.

Sterilisation in Place (SIP) is mainly used in pharmaceutical and biological production facilities and serves not only to clean but also to sterilise the system. Usually, sterilisation takes place through superheated steam or with special chemicals. The cleaning or sterilisation cycle can be optimised on site by integrating ozone into the process.

Catalogs

No catalogs are available for this product.

See all of relyon plasma GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.