- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

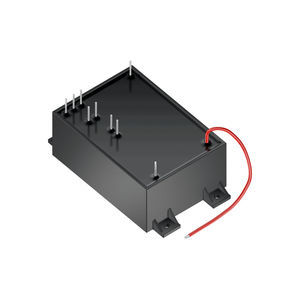

Industrial plasma generator PiezoBrush PZ3-iPDD

Add to favorites

Compare this product

Characteristics

- Type

- industrial

- Other caracteristic

- PDD

Description

The PiezoBrush PZ3-i cold plasma unit is designed for integration into new and existing production lines and is therefore compact, safe and efficient. It is particularly well suited for the pre-treatment of processes such as bonding, printing and laminating, thus ensuring process and product quality in equal measure. Due to its uniquely compact and robust design, the PiezoBrush PZ3-i can be quickly and easily integrated into production lines as well as partially to fully automated systems. In addition, comprehensive process control is possible in automated production processes, ensuring traceability. The device is also intuitive to operate and can be maintained without tools.

Applications

Inkjet, marking and pad printing

Bonding processes with epoxy, polyurethane and cyanoacrylates etc.

Potting and dispensing technology

Joining and assembly technology

Laboratory and medical technology

Packaging technology

Microbiology, microfluid and food technology

Fields of application

Activation of surfaces of a wide variety of base materials

Optimization of bonding, printing and lamination processes

Surface treatment of plastics, glasses, ceramics, metals, composites and natural materials

Selective improvement of the wettability of a wide variety of surfaces

Fine cleaning of surfaces

Alternative to chemical primers, flame treatment processes and mechanical roughening

With an average treatment width of 5 – 29 mm (CDA), the PiezoBrush PZ3-i is very well suited for the pre-treatment of adhesive grooves or for marking printing on low-energy materials.

VIDEO

Catalogs

PiezoBrush PZ3

8 Pages

PZ3-i

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.