Different surfaces must be activated with the appropriate accessories in each case to achieve a good result in the end. Depending on individual customer requirements, there are therefore different exchangeable modules that are suitable for both the PiezoBrush PZ3 handheld plasma device and the compact PiezoBrush PZ3-i integration solution. The device recognizes which module is currently being used and automatically adjusts the process parameters accordingly.

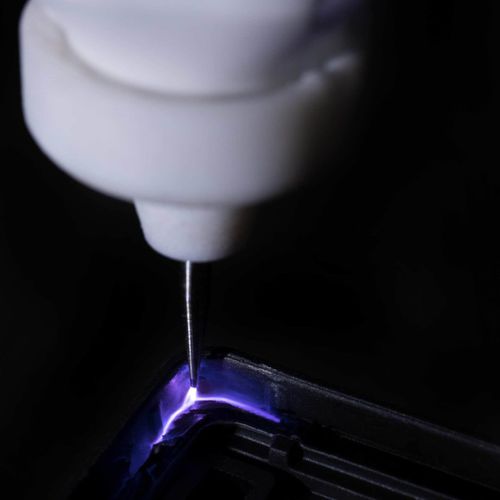

The PDD® technology used to generate the cold plasma of the PiezoBrush product series is based on the discharge of high electric fields. Therefore, the electrical conductivity of the component to be treated, for example, is of decisive importance when selecting the modules. A total of five different modules are currently available: the Standard module, the Nearfield module, the Needle module, the Nearfield Needle module and the Multigas module.

Module Standard is designed for surface treatment of non-conductive substrates such as plastics, ceramics, glass, natural fibers, leather, textiles and more. For effective treatment, a module-to-substrate distance of 2 to 10 mm is recommended. If uncontrolled flashovers occur during use on the substrate surface, e.g. metals or conductive polymers, the device switches off automatically after approx. 0.5 seconds. In this case, the surface is at least partially conductive and should therefore be treated with the Nearfield Module.

piezobrush® PZ3 Module Nearfield

The Module Nearfield is used for the treatment of (partially) electrically conductive materials such as metals, CFRP, indium tin oxide (ITO) or conductive plastics.