High-voltage atmospheric plasma generator PlasmaBrush PB3industrial

Add to favorites

Compare this product

Characteristics

- Type

- industrial, high-voltage

Description

The PlasmaBrush PB3 is our high-performance plasma system for all inline processes in industrial and high-speed applications. The PlasmaBrush PB3 is widely used in the automotive, packaging and printing sectors. The focus here is primarily on plasma cleaning and surface activation. This is primarily used to prepare the products for further downstream processes such as bonding, painting or printing.

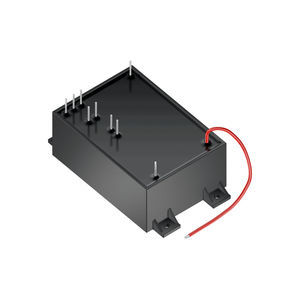

The PlasmaBrush PB3 is a combination of a particularly compact and long-term stable plasma generator in nozzle form, a unipolar pulsed high-voltage source and a vortex flow in the nozzle. The perfectly matched components in a robust industrial design are perfect for easy integration into any system.

Field of application

Automotive sector

Printers and printing industry

Packaging industry

Applications

Ultrafine cleaning

Reduction of oxide layers

Surface functionalization

Pre-activation for bonding, sealing, casting or printing

Coating, laminating and sealing

Germ reduction and sterilization

Print pre-treatment

The table below shows the surface energy of different plastics. In each case, the surface energy is shown after treatment with the PiezoBrush PZ3, the PlasmaBrush PB3 (plasma high-performance system) and without prior plasma treatment.

Advantages

Very compact design, also suitable for narrow grooves and hard-to-reach areas

Easy integration even in small robots (

Suitable for compressed air, nitrogen and other gases

Variable Power

High start-stop dynamics

Maximum operating reliability

VIDEO

Catalogs

PlasmaBrush PB3

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.