High-voltage plasma generator PlasmaBrush PB3 Integrationindustrial

Add to favorites

Compare this product

Characteristics

- Type

- industrial, high-voltage

Description

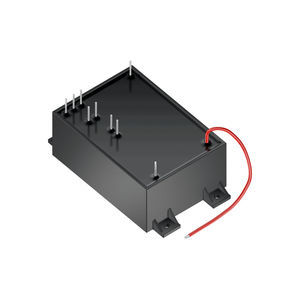

The PlasmaBrush PB3 Integration is a complete system with external compressed air connection, cable-connected operating unit, plasma generator and nozzle. It was developed for stationary use in production plants. The plasma unit can be controlled either by remote control or by connection to a higher-level control system. Integration is thus possible according to individual customer requirements.

Application

A gas monitoring and an internal gas maintenance unit are available on the PlasmaBrush PB3 Integration. The integrated gas flow meter (MFM) with minimum value and display on the unit provides information about the gas flow. The plasma generator is equipped with an additional holder and a fabric protection hose for the cable and the gas hose.

The manual control of the PlasmaBrush PB3 Integration is carried out via the remote control. For safe working, the remote control is equipped with an emergency stop button so that the process can be stopped immediately. Plasma generation cannot be restarted until the error has been acknowledged. If the gas supply is too low, the switch for plasma generation can not be operated. Due to the control with a superordinate plant control via PLC, an automated integration into the existing plant is also possible.

Fields of application

Surface activation and functionalization for optimized wettability

Coating for new surface properties

Plasma-assisted laminating processes and adhesive bonded joints

Plugging and sealing

Plasma-induced reduction of metal surfaces

Fine cleaning of metal, glass and plastics

Chemical-free bleaching of textiles

Sterilization of fabrics and thermally unstable plastics

Catalogs

No catalogs are available for this product.

See all of relyon plasma GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.