- Hydraulics - Pneumatics

- Valve

- Reverse acting rupture disc

- REMBE® GmbH Safety+Control

- Products

- Catalogs

- News & Trends

- Exhibitions

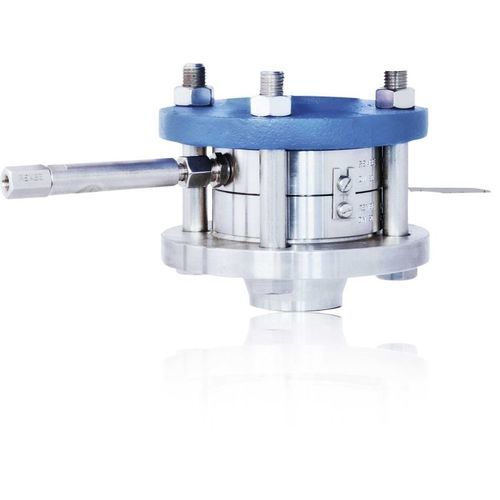

Reverse acting rupture disc KUB® Vmetal

Add to favorites

Compare this product

Characteristics

- Type

- reverse acting

- Material

- metal

- Nominal diameter

Max.: 800 mm

(31 in)Min.: 20 mm

(1 in)

Description

The KUB® is the only rupture disc to be manufactured using Euler's critical load formula to determine the burst pressure, creating the most robust, high-performance rupture disc available. Unlike other rupture disc solutions where a weak point is created in the metal, the KUB® is a unique, highly engineered solution, benefiting from a series of buckling pins which accurately collapse for reliable, full bore, opening. As there is no specific weak point on the rupture disc, the KUB® is an extremely robust solution, almost immune to damage by incorrect handling, improper installation or even being dropped! This maximises the lifespan of the disc and minimises long-term investment by lowering ongoing replacement costs. The KUB® features a two-layer design, with the smooth, unblemished surface of the sealing membrane facing the process minimising the possibility of damage due to corrosion.

The KUB® V rupture disc protects safety valves against corrosive solids or adhesive media and is installed upstream of the safety valve inlet. It is certified to resist a back pressure of 135 %* of the defined burst pressure and thus enables you to test safety valves in-situ without having to remove the valve for servicing.

Suitable for full vacuum and back pressure resistant, the KUB® with its non-fragmenting design can be installed upstream of a safety valve to isolate the valve from the process. When used in combination, the KUB® will ensure the best possible condition of the safety valve, significantly extending service intervals and overall life of the valve while maximising return on investment.

Catalogs

KUB V Product Information

1 Pages

Other REMBE® GmbH Safety+Control products

Reverse -Acting Rupture Discs

Related Searches

- Valve

- Pneumatic valve

- Stop valve

- Wedge gate valve

- Valve for the chemical industry

- Compact valve

- Valve for the food industry

- Valve for oil industry applications

- High-pressure valve

- Valve for the pharmaceutical industry

- Double-acting valve

- Knife gate valve

- Isolation valve

- Low-pressure valve

- Single-acting valve

- High flow rate valve

- Rembe rupture disc

- Rembe metal rupture disc

- Inverted bursting disc

- Stainless steel bursting disc

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.