- Environment - Health - Safety

- Building Security and Machine Safety

- Grounding device

- REMBE® GmbH Safety+Control

- Products

- Catalogs

- News & Trends

- Exhibitions

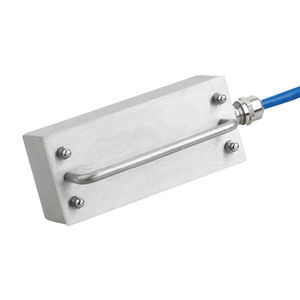

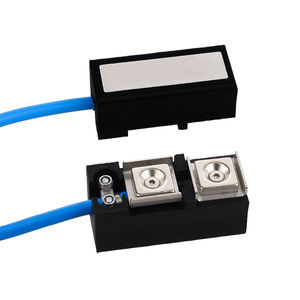

Grounding device SYMEGA. PRO

Add to favorites

Compare this product

Description

Symega grounding systems offer the best possible protection against electrostatic discharge during the process. Processes can be safely controlled or interrupted by continuously monitoring the resistance using grounding clamps and the potential-free changeover contacts connected to the monitoring system.

Application

The SYMEGA.PRO was developed for grounding when filling or emptying mobile containers such as tank trucks, IBCs, FIBCs, drums and etc. Grounding systems from the SYMEGA series are used in the chemical, food, pharmaceutical, cosmetics, oil and gas as well as wood industries.

Advantages

• One intelligent system for all applications.

• Capacity check of connected objects enables tamper protection.

• 24 VDC and 230 VAC power supply.

• Monitors the connection to the main ground.

• No loading fault due to loose contact.

• Safe grounding due to time limitation.

Mechanism

Electrostatic charges can build up as a result of the friction when flammable liquids, gases or solids are being loaded. The resulting electrostatic discharges (sparks) can be a risky ignition source for explosive atmospheres under the appropriate conditions. The SYMEGA.PRO continuously dissipates the electrostatic potentials to prevent these discharges. The grounding clamp is connected up to the object that has to be grounded (truck, drum, IBC, BigBags, etc.). If the SYMEGA.PRO detects the truck, the pumps, valves or mechanical conveyors connected to the grounding relay are activated for the filling process. The connection between the clamp and the object is permanently monitored.

Catalogs

No catalogs are available for this product.

See all of REMBE® GmbH Safety+Control‘s catalogsOther REMBE® GmbH Safety+Control products

Explosion Prevention

Related Searches

- Fixed reel

- Gas detector

- Cable reel

- Industrial detector

- Wire reel

- Monitoring detector

- Compact detector

- CO detector

- Semiconductor detector

- Stainless steel reel

- Process detector

- H2 detector

- Flammable gas detector

- Humidity detector

- Explosion-proof detector

- Fire detector

- Particle detector

- Grounding device

- Rembe ground clamp

- Dust detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.