- Environment - Health - Safety

- Building Security and Machine Safety

- Grounding device

- REMBE® GmbH Safety+Control

- Products

- Catalogs

- News & Trends

- Exhibitions

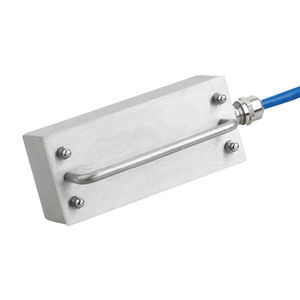

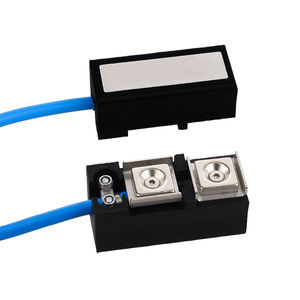

Grounding device SYMEGA.VO

Add to favorites

Compare this product

Description

Symega grounding monitoring systems offer the best possible protection against electrostatic discharge during the process. Processes can be safely controlled or interrupted by continuously monitoring the resistance using grounding clamps and the potential-free changeover contacts connected to the monitoring system.

Application

As part of a progressive automation process Symega systems are primarily used in the process, chemical and pharmaceutical industries. They make a significant contribution to plant safety by protecting against electrostatic charge in potentially explosive atmospheres.

Advantages

• Easy on-site installation thanks to its compact design.

• Integrated signalling for reliable monitoring.

• Approved for use in hazardous areas zones 1 and 21.

• Maximum safety through potential-free changeover contacts that are fully integrated into the process control system.

Mechanism

The SYMEGA.VO grounding monitoring system establishes a safe connection between stationary and mobile, metallic or conductive and dissipative objects and a good earth. The built-in LEDs signal the actual status of the grounding process. Thanks to the two built-in potential-free changeover contacts, this status can be fully integrated into the process control system and therefore represents the highest possible level of safety. The measurement can be carried out in two variants: low-impedance for potential equalisation of 0-1 kΩ or 103 Ω for all metallic objects and high-impedance for potential equalisation of 0-3 MΩ or 3 x 106 Ω for type C big bags.

Catalogs

Brochure Explosion Safety

56 Pages

Other REMBE® GmbH Safety+Control products

Explosion Prevention

Related Searches

- Fixed reel

- Gas detector

- Cable reel

- Industrial detector

- Monitoring detector

- Wire reel

- Compact detector

- CO detector

- Process detector

- Semiconductor detector

- Stainless steel reel

- H2 detector

- Flammable gas detector

- Explosion-proof detector

- Humidity detector

- Fire detector

- Particle detector

- Grounding device

- Rembe ground clamp

- Dust detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.