- Products

- Catalogs

- News & Trends

- Exhibitions

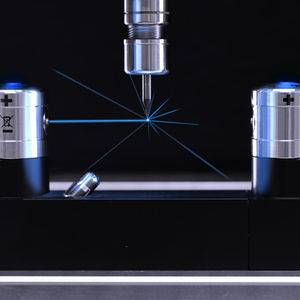

Non-contact touch probe NC4tool settingfor machine toolshigh-precision

Add to favorites

Compare this product

Characteristics

- Type

- tool setting

- Applications

- for machine tools

- Other characteristics

- high-precision, high-speed, rugged, non-contact

Description

NC4 non-contact tool setters provide high-precision, high-speed tool measurement and broken tool detection, allowing process control on all sizes and types of machine tools.

During machining processes, dimensional accuracy is dependant upon several variables, including tool size deviation, tool run-out and tool breakage.

Renishaw's NC4 systems allow users to control these variables, enabling measurement of a wide variety of tools at production feeds and speeds, while minimising the risk of excessive tool wear or tool breakage – an important consideration for small and fragile tools.

NC4+ Blue fixed systems

Featuring industry-first blue laser technology and improved optics, Renishaw's NC4+ Blue systems are available with an operating gap of up to 240 mm and deliver a step change in tool measurement accuracy, proven to industrial standards.

All systems feature an integral air blast as standard to enable accurate and reliable tool measurement.

NC4 separate systems:

Renishaw's separate systems offer the same on-machine tool measurement and broken tool detection functionality as their fixed system counterparts.

Users can set these systems up in a range of configurations depending on the application – giving users the ultimate flexibility.

Separate systems are available with an operating gap of up to 5 m.

Custom solutions:

Renishaw provides bespoke NC4 systems to suit specific applications – including a range of sizes, mounting configurations and additional integrated probing systems; for example, contact tool setters for turning tools.

VIDEO

Catalogs

Related Searches

- Measuring machine

- Optical measuring machine

- High-precision measuring machine

- RENISHAW touch probe

- Parts measuring machine

- Distance measuring machine

- Control measuring machine

- RENISHAW measurement touch probe

- Diameter measuring machine

- Laser measurement system

- Compact measuring machine

- Length measuring machine

- CNC measuring machine

- High-speed measuring machine

- Alignment system

- RENISHAW compact touch probe

- Temperature measurement system

- Gauge measuring machine

- Laser alignment system

- Linear measurement touch probe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.