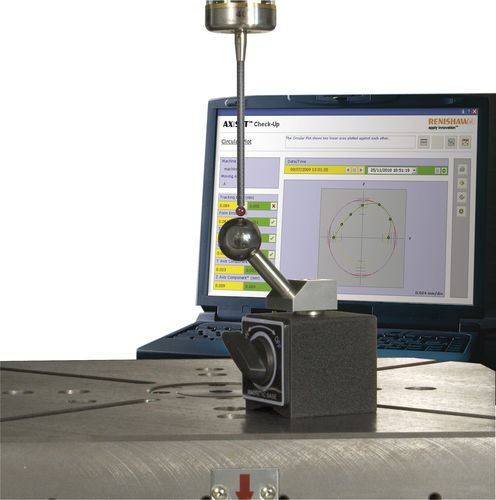

Fast, automated health checks for multi‑axis machine tools.

AxiSet™ Check-Up is a cost-effective solution for checking and improving rotary axis performance

AxiSet Check-Up offers an easy and reliable process for analysing the performance of rotary axes and for identifying problems caused by incorrect machine set-up, collisions or wear. In just a few minutes, users of multi-axis machining centres and multi-tasking machines can identify poor machine alignment, geometry and pivot point errors that can cause extended process setting times and non-conforming parts. Where possible, AxiSet Check-Up automatically corrects on-machine pivot point parameters.

Reduce scrap, enhance productivity and increase profits – Renishaw machine tool probes can keep your machining process under control.

Reduce scrap, enhance productivity and increase profits – Renishaw machine tool probes can keep your machining process under control.

Data analysis made simple

The AxiSet Check-Up app graphically displays the measurement data produced by the AxiSet Check-Up macro software.

The app provides graphical representations of multi-axis machine performance data that can help to make PASS or FAIL decisions based on defined tolerances. Machine performance can be tracked over time, using the app's historical data chart function.