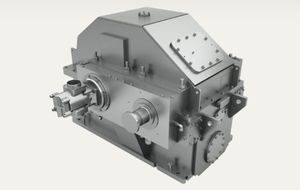

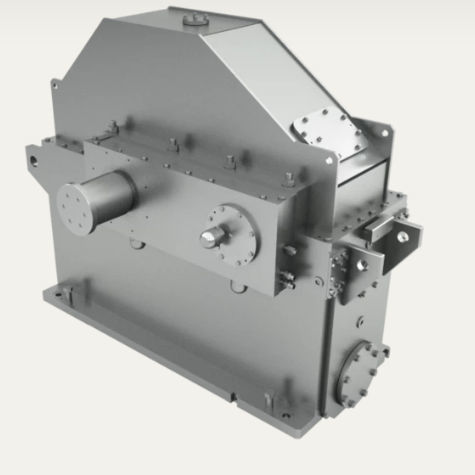

Helical gearbox TA..Isingle-stagehigh-speedshaft

Add to favorites

Compare this product

Characteristics

- Type

- helical

- Number of stages

- single-stage

- Performance

- high-speed

- Applications

- shaft

- Rotational speed

Max.: 20,000 rpm

(125,663.71 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Power

Max.: 20,000 kW

(27,192.42 hp)Min.: 0 kW

(0 hp)- Gear ratio

Max.: 11 unit

Min.: 1 unit

Description

API gearbox design with fixed center distances and pre-engineered standard to meet the highest requirements.

Our innovative turbo gearboxes have been the source of continual gains in efficiency in the energy production and process technology fields for years now. The TAI range was designed especially for the special engineering requirements of the oil and gas industry. It is a standardized, single-stage gearbox concept for high-speed applications. This gear unit type is available in six housing sizes with fixed center distances.

Innovations from RENK have nearly halved power losses in turbo gearboxes over the past 20 years and have played a key role in helping our customers to significantly boost the efficiency of their systems.

The main feature of these RENK turbo gearboxes are the case-hardened, precisely machined flanks of the teeth, which are designed for API, AGMA, DIN, and ISO requirements according to the respective application. Every design is based on detailed rotordynamic calculations for all operating points. The geometries of our radial and axial bearings are therefore precisely optimized according to the respective application scenario as well as the operating conditions.

Features

Suitable for absorbing axial forces

Short shaft overhangs for the best rotordynamic vibration characteristics

Welded construction – adaptable to specifications / customer requests

Best possible efficiency that can be achieved by conventional means

Optimized gear tooth geometry in terms of efficiency, noise, and vibration excitation

Individually calculated, optimal bearing geometries for every application scenario

Short delivery time due to high availability of stock

Catalogs

No catalogs are available for this product.

See all of RENK GmbH‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Precision gearbox

- Flexible shaft coupling

- Compact gearbox

- Gear train gearbox

- Shafts coupling

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gearbox

- Single-stage gearbox

- Bevel gearbox

- Multi-stage gearbox

- High-performance gearbox

- Two-stage gearbox

- Electric motor gearbox

- Torque shaft coupling

- Rigid shaft coupling

- Flange gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.