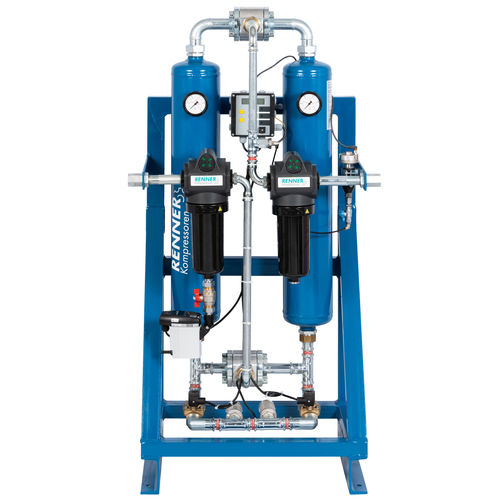

The cold-regenerating adsorption dryers of the RAT-40 series are a comprehensive air treatment system with mounted pre- and after-filter as well as an automatic condensate drain. The RAT-40 uses a high-quality desiccant which removes moisture from the compressed air and ensures a safe production process.

Adsorption dryers are typically built with two drying vessel to regularly regenerate the desiccant so it regains its drying capacity. The first vessel dries the incoming compressed air while the second vessel is being regenerated. Each vessel switches tasks when the other vessel is completely regenerated.

The standard version has a fixed cycle time with which the containers alternate with adsorption and desorption. Thus, the regeneration air requirement remains constant.

The Superplus version is equipped with a dew point-dependent capacity control. A continuous dew point measurement takes place at the compressed air outlet. The vessel switches tasks only when the desiccant is completely loaded, the regeneration air saved in this way improves the economic efficiency of the dryer.

Advantages

Quick and easy commissioning – complete turnkey system with coordinated components

High-quality compressed air due to mounted pre- and afterfilter as well as automatic steam trap

Low space requirement due to compact build

Saving of regeneration air thanks to coupling with compressor and intermittent operation

Reduction in operating costs by adapting the adsorption times to the actual water input (for SuperPlus version)