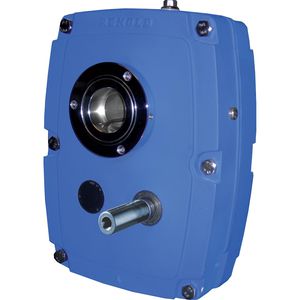

Worm gear spiralshaftedsteel

Add to favorites

Compare this product

Characteristics

- Type

- worm

- Teeth

- spiral

- Configuration

- shafted

- Material

- steel

- Applications

- transmission

- Other characteristics

- precision

Description

Renold manufactures worm gears using the 'Holroyd' tooth form which conforms to British standard 721. The leaving side contact pattern provides for a good oil entry which results in the following benefits:

Increased lubrication

Increased efficiencies

Smoother running

Renold worm gears are widely respected for performance and reliability in a wide variety of drives ranging from large steel mill screw down mechanisms to high precision dual lead machine tool and rotary positioning systems.

Unrivalled Accuracy

Although Renold produces worm gears to BS 721, for greater control of manufacturing tolerances we use DIN 3962 and DIN 3974 for specifying grades of quality. Manufacturing quality is backed up by the latest inspection techniques and for high precision gears sets we can supply, in graph format, results of pitch, profile and transmission variations over 360 degrees of the worm gear set.

Approvals

Renold Gears is BS EN ISO 9001:2008 approved. All products are designed and manufactured within this Quality Assurance system.

Applications

Mining, Coal cutting machines, axle drives, civil engineering, cranes, trucks, dumpers, steel plants, screwdowns, wire and tube drawing, automotive, oil pump, fuel injection, power, coal pulverisers, steam turbines, machine tools, indexing heads, rotary tables

Catalogs

No catalogs are available for this product.

See all of RENOLD‘s catalogsRelated Searches

- Right angle gearbox

- Flexible shaft coupling

- Gear train gearbox

- Compact gearbox

- Shafts coupling

- Transmission gearbox

- Shaft gearbox

- Helical gear gearbox

- Flange shaft coupling

- Transmission chain

- Bevel gearbox

- Torque shaft coupling

- Modular gearbox

- Flange gearbox

- Parallel-shaft gearbox

- Metal chain

- Transmission shaft coupling

- Roller chain

- Compact shaft coupling

- High load capacity gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.