- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

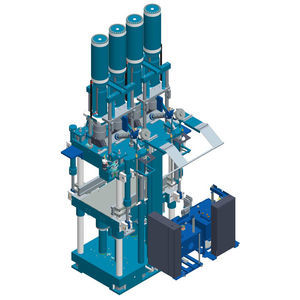

Vertical injection press S01Y10electricfor rubber

Add to favorites

Compare this product

Characteristics

- Closure

- vertical

- Operation

- electric

- Treated material

- for rubber

- Clamping force

1,000 kN

Description

Duplicate molding of cables under tension in the mold

The S01 has been specially designed for that purpose !

This press is designed for a highly specific use:

Rubber overmolding of cables designed for cutting stones.

The cables must be positioned in the mold in the stretched position, and overmolding takes place successively, “step-by-step”.

A mechanical choice dictated by the application

The “C-Frame” structure, with a 1,000 kN mould clamping force, has been tailored to this press, because this technology offers access to all sides of the mold – something which is essential for successfully undertaking this very special overmolding.

Injection and clamping are, therefore, performed via the top because the platen where the cables to be overmolded are distributed is highly accessible and at a constant level.

This area comprises a system, on either side of the mold, which clamps and stretches four cables simultaneously, thereby positioning them and ensuring the precision of the molded part.

The heating platen fitted in this press also comprises a special temperature regulation mechanism, so that two areas of the mold can be managed at different temperatures.

Dimensions of heater plates : 1000 x 500 mm

Injection capacity: 1000 cm3

Catalogs

No catalogs are available for this product.

See all of REP international‘s catalogsRelated Searches

- REP injection molding machine

- Horizontal injection press

- Hydraulic injection press

- Thermal regulator

- REP electric injection molding machine

- REP vertical injection molding machine

- Molding machine

- Automatic molding machine

- REP rubber injection molding machine

- Programmable thermal regulator

- LSR injection molding machine

- Multi-component injection molding machine

- Modular injection molding machine

- Injection molding machine temperature regulator

- Parts with insert injection molding machine

- Vertical molding machine

- Adjustable molding machine

- Compression molding machine

- Temperature regulator without display

- Composite molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.