- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Analysis software suite REP Net 4.0monitoringmanagementsynchronization

Add to favorites

Compare this product

Characteristics

- Function

- analysis, monitoring, management, synchronization, reporting, quality, simulation, visualization, modeling, calculation, optimization, process control, deformation monitoring, control

- Applications

- industrial, for production, process

- Type

- real-time

- Deployment mode

- online

- Other characteristics

- all-in-one, high-performance

Description

Your production line at your fingertips and at a glance

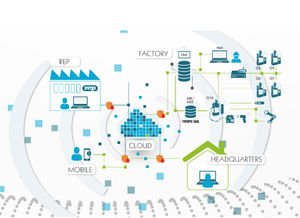

REP Net 4.0 is a software program used to link the presses to a centralized data system

This user-friendly system using Windows checks the process quality in real time, centralizes the mold settings and follows the production schedule.

We are now in the fourth generation of presses network, since the 1st version of repnet in 1987.

REP Net 4.0 is provided with a simplified web interface.

allows to be alerted in real time on the status of the workshop!

REP Net 4.0 fits into Industry 4.0 and provides:

• Cycle traceability (set value, measured value, SPC calculation)

• Mould settings transfer and centralizing

• Help for production management, workshop modelling

Real time follow-up

Management of the production progress and anticipated series changes

CIM Concept (Computer Integrated Manufacturing):

Supervision and coordination of the production operations and flows to follow the input and availability of the presses.

REP Net 4.0 can share its data with the company's management systems (ERP, MES, etc.) via the OPC UA protocol, the widely used communication standard within the scope of Industry 4.0

Centralized settings

Workshop flexibility

The process setting database is used to transfer the settings and easily change the productions between the presses.

Traceability

Permanent guarantee of the production stability

SPC Concept (Statistical Process Control) :

Record of the set values, measured values and supervision of the process stability and conformity.

Catalogs

Related Searches

- Software suite

- Management software suite

- Process software suite

- Analysis software suite

- Monitoring software suite

- Real-time software suite

- Quality software suite

- Industrial software suite

- Reporting software suite

- Simulation software suite

- Visualization software suite

- All-in-one software suite

- Data collection software suite

- Control software suite

- High-performance software suite

- Modeling software suite

- Optimization software suite

- Process control software suite

- Production software suite

- Calculation software suite

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.