- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

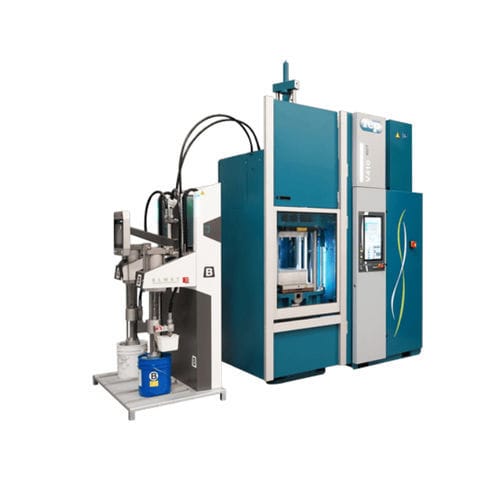

Robotic loading cell for injection molding machines

Add to favorites

Compare this product

Characteristics

- Function

- loading

- Applications

- for injection molding machines

Description

Flashless Liquid Silicone Molding

With our customers' requirements in mind, we strive for new developments by offering turnkey solutions in line with the current concerns: driving industrial productions towards sustainable development!

The demonstration made with this application for fuel cell gaskets offers a standardized, easily configurable design for various applications.

Based on this concept, REP wants to contribute, beyond automation, to sustainable development: transition to e-mobility and hydrogen, wasteless molding, energy-efficient solutions, flexible reusable means for increased lifespan.

A fully automatic process !

Benefits:

A technically sophisticated configuration

Adaptation to the technically most sophisticated and demanding processes

Flashless, waste-free molding

Perfect and uniform clamping quality over the whole surface

Maintenance-free durability over time

Outstanding injection precision and exactitude granted

Stability and repeatability designed for automation

Low consumption (servo-motor - insulation)

100% robot-controlled and automated Production

"Plug & Automate" Concept

Easy to install

Highly flexible

Insert loading

Plasma activation of the molded surface

Part demoulding and receiving

Visual compliance testing

Equipment

V410 Extended – 50 cm3 LSR

Automated cell made by REP

LSR dosing system

Flashless single-cavity mold

CRB with 4 shut-off nozzles

Application example

LSR Fuel Cell Gasket

Insert dimension: 290 x 160 mm (thickness 0.1 mm)

Specific stainless steel

Gasket overmolding

Low gasket thickness

LSR volume of the gasket: 3.1 cm3

VIDEO

Catalogs

No catalogs are available for this product.

See all of REP international‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.