- Metrology - Laboratory

- Optical Component

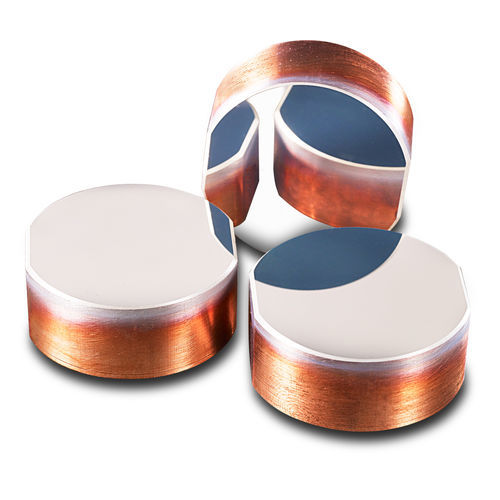

- Spherical mirror

- Research Electro-Optics

CO2 laser mirror sphericalcylindricalcopper

Add to favorites

Compare this product

Characteristics

- Shape

- spherical, cylindrical

- Material

- copper

- Use

- for CO2 laser, precision

- Options and accessories

- high-reflectivity

Description

Excelitas offers a range of copper high reflectors designed for use with high-power CO2 lasers to enable beam delivery and beam shaping. These laser mirrors offer a combination of high reflectivity >99.7% at 10.6 μm, excellent surface quality (40-20) and low scatter with surface roughness <50Å. Produced from oxygen-free, high thermal conductivity (OFHC) copper, these reflectors deliver superior optical performance and maximum laser damage threshold.

These CO2 laser mirrors can be fabricated with plano, spherical or cylindrical surfaces and can range from 6 mm to 150 mm in size. Through the use of holes, mounting flanges and other mechanical features can be easily accommodated. In addition, Excelitas can employ its traditional electron beam (e-beam) or Advanced Plasma Source (APS) coating technologies in order to deliver the precise combination of durability, damage resistance and cost characteristics required for a specific application. Furthermore, the optics are handled in a controlled environment throughout the manufacturing process, thus preventing any deterioration of the pristine optical surfaces prior to coating, and maximizing thin film adhesion and laser damage threshold.

Catalogs

No catalogs are available for this product.

See all of Research Electro-Optics‘s catalogsRelated Searches

- Glass lens element

- Optical filter

- Optical prism

- Spectrum lens element

- Optical window

- Colored optical filter

- Glass optical prism

- Visible lens element

- Round mirror

- Laser lens element

- Crystal lens element

- Glass mirror

- Spherical lens element

- UV lens element

- Round optical window

- Laser mirror

- Beamsplitter

- Optical glass lens element

- Infrared optical filter

- Polarizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.