- Metrology - Laboratory

- Optical Component

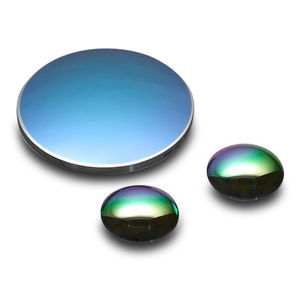

- Zinc selenide lens element

- Research Electro-Optics

CO2 laser lens element zinc selenidegermaniumzinc sulphide (ZnS)

Add to favorites

Compare this product

Characteristics

- Material

- zinc selenide, germanium, zinc sulphide (ZnS)

- Optical characteristics

- infrared

- Applications

- for CO2 laser

Description

Excelitas high-precision infrared CO2 laser lenses are customized from a variety of substrate materials, including Ge, ZnSe, ZnS, and Cleartran. Using our substrate fabrication and coating leading-edge process technologies, our CO2 laser lenses minimize subsurface damage for excellent Laser Damage Thresholds.

Excelitas consistently delivers optics with exceptional laser damage resistance characteristics due to our highly controlled processes for fabricating, coating, and laser-damage testing in our state-of-the-art facilities, with a unique capability of in-house laser damage testing. This vertical integration is critical for enabling careful control over every aspect of the design and manufacturing process to achieve a high damage threshold reliably. This process includes precise specification and thorough inspection of incoming raw materials, followed by shaping and polishing the components to minimize subsurface damage and contamination. Thin film coatings are then designed and deposited using our techniques that avoid contamination and limit electric field effects. In addition, our broad well-equipped in-house laser damage testing lab includes several different laser pulse widths and wavelengths.

Catalogs

No catalogs are available for this product.

See all of Research Electro-Optics‘s catalogsRelated Searches

- Glass lens element

- Optical filter

- Optical prism

- Spectrum lens element

- Optical window

- Colored optical filter

- Glass optical prism

- Visible lens element

- Round mirror

- Laser lens element

- Crystal lens element

- Glass mirror

- Spherical lens element

- UV lens element

- Round optical window

- Laser mirror

- Beamsplitter

- Optical glass lens element

- Near-infrared optical filter

- Polarizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.