Epoxy resin 102 series laminating

Add to favorites

Compare this product

Characteristics

- Type

- epoxy

- Applications

- laminating

Description

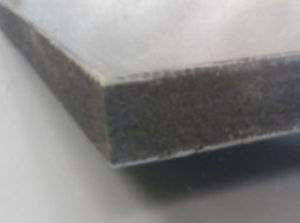

RESOLTECH 1020 ECO is a room temperature epoxy laminating biobased system for wood-epoxy, concrete reinforcement and metal constructions that are inherently moving structures.

In boat building, it may be used for all woods types lamination, coating, scarfing and strip planking.

Thanks to its low viscosity and a wide range of hardeners (13 min to 11h30min), it allows applications in both traditional wet layup, vacuum bagging or under press. A thixotropic version, the 1020T ECO is available for vertical or overhanging applications prone to dripping.

The mixing ratio for all hardeners is 100:30 by weight. All hardeners are compatible and can be mixed in order to obtain intermediate reactivities.

The 1020 ECO exceptional wettability makes hand lamination easier to the workers while guaranteeing a safer work place due to the low toxicity of this system, it contains no CMR components and complies to the latest REACH European regulation.

The 1020 ECO resin system is also widely used in civil engineering applications on glass and carbon laminates where its little sensitivity to humidity during its application and good curing properties at ambient temperature are appreciated.

With 40% of biobased carbon atoms in the resin part, the use of 1020 ECO will reduce the carbon footprint of composites structures making no concessions on thermo-mechanical performances.

40% biobased on resin part*

Adjustable pot life from 13mn to 11h30mn

Good elongation characteristics

Little sensitivity to humidity during application

Mix density

1.08

Gel time on 70 mL, 4cm at 23°C

13m - 11h30m

TG (°C)

75

Mix viscosity (mPa.s)

205 - 457

Catalogs

No catalogs are available for this product.

See all of Resoltech‘s catalogsRelated Searches

- Epoxy resin

- Resin for electronic applications

- Acrylic varnish

- Composite resin

- Low-viscosity resin

- High-performance resin

- Laminating resin

- High-temperature resin

- Impregnation resin

- Topcoat

- Casting resin

- Transparent varnish

- Resin for marine applications

- Fire-resistant resin

- Resin for the automotive industry

- Injection resin

- Epoxy gelcoat

- Topcoat for marine applications

- Composite gelcoat

- Epoxy varnish

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.