- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

3D level scanner 3DPro2300radar

Add to favorites

Compare this product

Characteristics

- Type

- 3D

- Other characteristics

- radar

Description

The 3DPro2300 radar scanner accurately detects the 3D information of solid materials and buildup on silo walls. It integrates image processing technology, big data analysis, artificial intelligence, machine learning, 3D point cloud conversion, 3D modeling, and cloud storage. This integration solves critical issues in material storage and level measurement, making material management intelligent and visible.

Not affected by complex working conditions

Using terahertz radar signals, it can function normally in environments with dust, rain, and fog. It enables automated inventory and measurement 24/7, replacing manual measurement, improving measurement speed and accuracy, and providing real-time inventory information.

High measurement accuracy, no blind spots

With a high-frequency microwave of 140GHz, this system enables 180°×360° omnidirectional measurement without any blind spots. It provides high angular resolution and up to 16,200 measurement points, guaranteeing precise three-dimensional modeling.

Different data formats for user decision-making

One example of such a format is the three-dimensional image display. It allows users to view material quality, volume, and level data information simultaneously. This format provides the necessary information for procurement, finance, and warehousing departments.

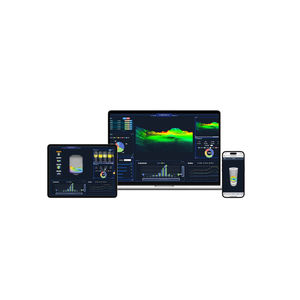

Inventory management only requires a phone

Cloud processing technology enables the transmission of measurement data to cloud servers for real-time data collection and monitoring. Users can access and control devices remotely from multiple terminals, allowing on-site maintenance without physical access.

Catalogs

RETTAR Product Catalog

42 Pages

Related Searches

- Level limit switch

- Level probe

- Liquid level limit switch

- Liquid level probe

- Analog level probe

- Protection level level switch

- Stainless steel level limit switch

- Storage tank level probe

- Liquids level indicator

- Solid level limit switch

- Water level probe

- Ultrasonic level sensor

- Radar level sensor

- IP67 level limit switch

- Solid level probe

- Compact level limit switch

- Electronic level indicator

- Compact level sensor

- Tank level indicator

- High-precision level probe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.