- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

3D scanner 3DPro 2500measurementlaserinfrared

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3D

- Applications

- measurement

- Technology

- laser, infrared

- Other characteristics

- high-resolution, high-precision

Description

The 3DPro2500 laser scanner can accurately measure the three-dimensional information of materials, adopting laser ranging technology. It is received by a photoelectric sensor inside the laser sensor.By measuring the flight time of the laser beam from emission to reception, the distance between the material surface and the laser sensor can be obtained.

The 3DPro2500 laser scanner uses a two-dimensional laser sensor to rotate or move the laser beam on a certain plane for two-dimensional measurement. On this basis, it is combined with a precision synchronous rotating pan head to drive the two-dimensional laser sensor to rotate on another dimension, achieving three-dimensional scanning of the material surface.

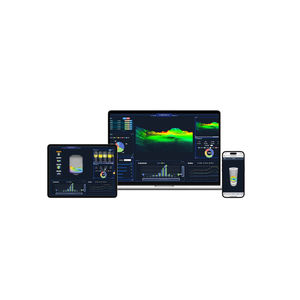

The cloud server combines technologies such as image processing, big data analysis, AI artificial intelligence, machine learning, cloud storage, and computing to analyze and convert the 3D point cloud data of the material surface, establish a high-precision and high-resolution 3D model, and calculate the quality, volume, level, and other related parameter information of the material based on this.

The 3DPro2500 laser scanner can operate automatically and continuously 24 hours, quickly measure and accurately obtain three-dimensional information in real time, thereby obtaining material purchase and sales, inventory data, as well as the three-dimensional shape of material distribution. It achieves intelligent, information-based and accurate material yard management, data visualization, process transparency, and unmanned on-site automation.

Catalogs

RETTAR Product Catalog

42 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.