- Production Machines

- Forming Machine

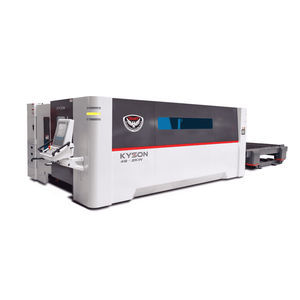

- 3-roller plate bending machine

- Revolution Machine Tools

3-roll plate bending machine F-FAB serieselectric

Add to favorites

Compare this product

Characteristics

- Number of rollers

- 3-roll

- Operation

- electric

Description

F-FAB Series

3 Roll Plate Roll

Bending Length 6′ – 20′

Bends Aluminum, Mild Steel, and Titanium

DESIGNED IN THE USA

As with all RMT designs, these special rolls are designed and engineered here in the USA. Built with quality components and extremely intelligent design, these rolls are built to last decades. No other machines match the speed, simplicity and precision for the aviation industry as the RMT F-Series machines. These machines bend aluminum or titanium alloyed sheets even with one or more radius, including hyperbolic shapes, to get precise cylindrical or tapered forms. The RMT R&D teams experience and expertise can even help create custom machines to solve any problem specific to your project.

RED MACHINE GIVES YOU WIIIIIINGS!

There was a time when several companies fought over the aircraft and aerospace industry in forming leading edge’s, helicopter propellers, and other special projects. Almost all of those companies are gone now and their used machines are very difficult to find. RMT F-Series Rolls have filled the need and brought back with even more unique features the machine that makes these difficult parts, simple again.

PRECISE AND POWERFUL

The movement of the upper beam is powered by separate dual speed AC motors, gearboxes, screw jacks and zero backlash couplings. Upper beam positions are monitored by very sensitive linear encoders and digital readouts. Top and bottom rolls are driven by a high torque dual speed AC motor and gear set. Gearbox rotation transferred to the rolls by sensitive cardan joints. The strong magnetic disk brakes prevent the sheet from sliding back during pre-bending operation.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.