- Metrology - Laboratory

- Optical Component

- Pulsed laser

- Revolution Machine Tools

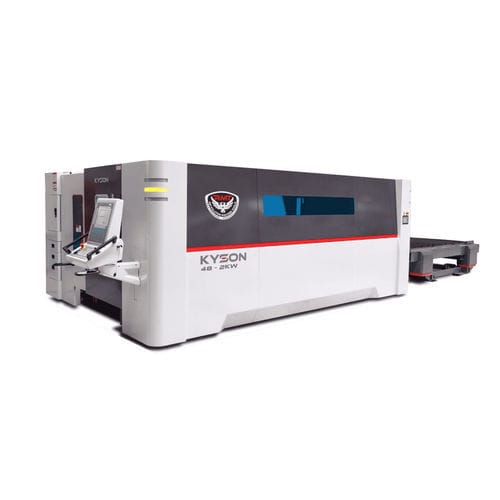

Pulsed laser KYSON 48fibercuttingcooled

Add to favorites

Compare this product

Characteristics

- Operational mode

- pulsed

- Technology

- fiber

- Applications

- cutting

- Other characteristics

- cooled, ytterbium fiber

- Power

Max.: 15,000 W

Min.: 2,000 W

- Wavelength

1,070 nm

Description

LASER LIGHT SOURCE AND CHILLER

RMT has partnered with industry leaders for the highest quality laser light sources on the market. Ytterbium fiber lasers operating at the 1070 nm wavelength are perfect for laser cutting. The operating wave-length, multi-kilowatt power, good beam quality, wide operating power range, power stability and small spot size on our laser are perfect for most cutting applications. Fiber lasers have a wide dynamic operating power range and the beam's focus and position remain

constant, even when the laser power is changed, allowing consistent processing results every time. A wide range of spot sizes can be achieved by changing the optics configuration. These features enable the end user to choose an appropriate power density for cutting various materials and wall thicknesses.

The laser light source chiller is a closed-loop liquid cooling system. The temperature of the light source is constantly monitored by the chiller, ensuring the light source is running at optimal temperatures. The standard cooling system will protect the laser in an environment up to +190 °F.

ROBUST FRAME CONSTRUCTION

A heavier frame means less vibration and better accuracy. The machine frames are reinforced to minimize twists and deformation while the robust frame of the machine is joined to the chassis by steel bars.

The machine frame goes through a heat treatment process for welding stress relief. Our RMT KYSON frames are machined with 5 axis CNC machining centers with single reference fixing. This keeps all axis parallel and the surfaces of the machine precise which provides great accuracy and longevity to the machine.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Revolution Machine Tools‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.