- Detection - Measurement

- Flow, Pressure and Level Measurements

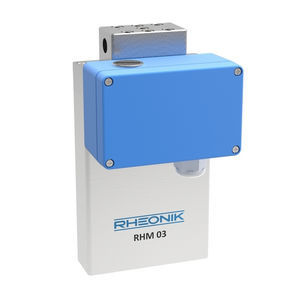

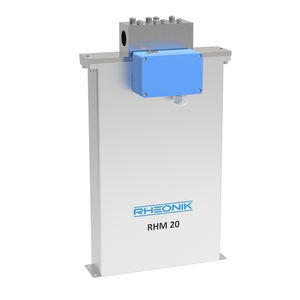

- Coriolis flow sensor

- Rheonik Messtechnik GmbH

Coriolis flow sensor RHM 06massfor liquids

Add to favorites

Compare this product

Characteristics

- Technology

- Coriolis

- Type

- mass

- Applications

- for liquids

Description

The RHM 06 is a low risk, low maintenance solution for critical flow applications everywhere. High pressure and temperature options comined with a selection of wetted material make the RHM 06 a true fit and forget device.

Materials: SS 316L / SS 316Ti, Super Duplex – 1.4410, Alloy C22 – 2.4602

Process Connection: ½" up to 1"

General Specifications

Serial Tube / Single Path

Flow rates Qmax, Qnom and Qmin for "serial" sensors will be 50% of the above listed parallel/dual path version.

Operating Temperature

For integral transmitter versions please refer to transmitter datasheet

Ambient Temperature

-50 °C to +80 °C (-60 °F to +180 °F) (standard), versions available for installation in vacuum chamber (-260 °C / -430 °F) or oven (up to +210 °C / +410 °F) (optional)

Electrical Connection Sensor

w/o Integral Transmitter

M20 x 1.5 standard cable entry for JM, SM terminal box versions

Optional entries available : ½" NPT or M25 x 1.5 (only for SM) or ¾" NPT (only for SM)

M16 x 1.5 standard cable entry for PM terminal box version

Max. cable length to remote RHE transmitter 100 m/330 ft

Sensor Enclosure Materials

Stainless steel 304 (standard), SS 316 (optional)

Coated aluminum terminal box, SS 316 terminal box (optional)

Wetted Materials

Flow tubes SS 316L or SuperDuplex

Manifolds SS 316L, seals FKM, FFKM, FVMQ

Standard flanges SS 316Ti, other connections SS 316L

Additional/customer specific materials available upon request

Process Connections

Nearly any – the Rheonik AnyPipeFit Commitment. Consult factory for types/sizes not listed in this data sheet on the Mechanical Construction pages

Related Searches

- Flowmeter

- Liquid flowmeter

- Stainless steel flowmeter

- Waterproof flowmeter

- In-line flowmeter

- Precision flowmeter

- Water flowmeter

- Mass flowmeter

- Flange flowmeter

- IP65 flowmeter

- Explosion-proof flowmeter

- Flow sensor

- Aluminum flowmeter

- DN25 - 1" flowmeter

- DN50 - 2" flowmeter

- High-accuracy flowmeter

- ATEX flowmeter

- DN80 - 3" flowmeter

- DN100 - 4" flowmeter

- IP67 flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.