- Detection - Measurement

- Flow, Pressure and Level Measurements

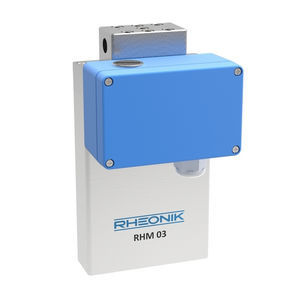

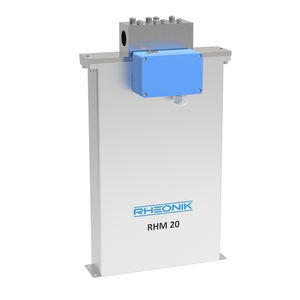

- Coriolis flow meter

- Rheonik Messtechnik GmbH

Coriolis flow meter RHM 80massfor waterfor corrosive fluids

Add to favorites

Compare this product

Characteristics

- Technology

- Coriolis

- Type

- mass

- Fluid

- for water, for corrosive fluids

- Pipe diameter

- DN150 - 6", DN175 - 7", DN200 - 8", DN225 - 9", DN250 - 10"

- Installation

- flange

- Material

- stainless steel

- Protection level

- rugged, IP65, IP66

- Applications

- for high flow rates

- Other characteristics

- high-temperature

- Mass flow rate

Min.: 100 kg/min

(220.46 lb/min)Max.: 8,000 kg/min

(17,636.98 lb/min)- Process temperature

Min.: -196 °C

(-321 °F)Max.: 350 °C

(662 °F)- Process pressure

Min.: 0 bar

(0 psi)Max.: 341 bar

(4,945.79 psi)- Precision

0.1 %

- Repeatibility

0.05 %, 0.1 %

Description

The RHM 80 excels in tough applications where high temperatures, pressures and corrosive fluids are present. Its heavy duty construction withstands extreme applications without losing Coriolis meter performance.

Materials: SS 316L / SS 316Ti, Super Duplex – 1.4410, Alloy C22 – 2.4602

Process Connection: 6" up to 6"

General Specifications

Electrical Connection Sensor

w/o Integral Transmitter

M20 x 1.5 standard cable entry for JM, SM terminal box versions

Optional entries available : ½” NPT or M25 x 1.5 (only for SM) or ¾” NPT (only for SM)

Max. cable length to remote RHE transmitter 100 m / 328 ft

Wetted Materials

1.4571 (SS 316Ti), 1.4410 (SuperDuplex) - standard

2.4602 (Alloy C22) - consult Factory

Additional/customer specific materials available upon request

Process Connections

Nearly any – the Rheonik AnyPipeFit Commitment. Consult factory for types/sizes not listed in this data sheet on the Mechanical Construction pages

Pressure Rating Compliance

Europe – PED: Module A2, Module B3.1+C2

Canada – CRN: Canadian Registration Number

Certifications and Approvals

North American Approvals Class I, Div. 1, 2, Gr. A,B,C,D, Zone 0, 1, 2

MID custody transfer approval (OIML R117)

American Bureau of Shipping (ABS) Product Type Approval for use on marine vessels

Testing and Inspection

All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate Customized calibration and testing services are available

Project Documentation and QA, Services

Rheonik offers a full set of services for large and complex engineering projects

Typical services offered are, but not limited to:

•Certificates of origin and conformity, mill certificates

Catalogs

RHM80

8 Pages

Related Searches

- Flowmeter

- Liquid flowmeter

- Stainless steel flowmeter

- Waterproof flowmeter

- In-line flowmeter

- Precision flowmeter

- Water flowmeter

- Mass flowmeter

- Flange flowmeter

- IP65 flowmeter

- Explosion-proof flowmeter

- Aluminum flowmeter

- DN25 - 1" flowmeter

- DN50 - 2" flowmeter

- High-accuracy flowmeter

- ATEX flowmeter

- DN80 - 3" flowmeter

- DN100 - 4" flowmeter

- IP67 flowmeter

- Remote flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.